- I-150m emazantsi, indlela eNtshona yeDingWei, iNanlou Village, idolophu yaseChangan, indawo yaseGaoCheng, eShijiazhuang, eHebei, eTshayina

- monica@foundryasia.com

Disemba 27, 2023 13:58 Buyela kuluhlu

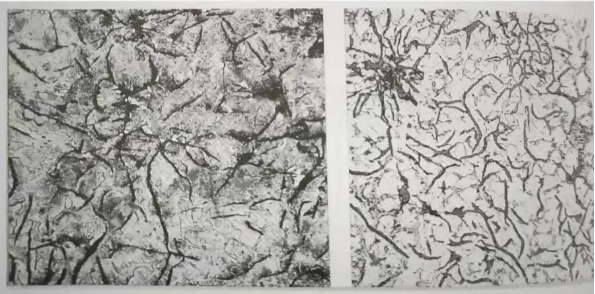

Ulwakhiwo lweMetallographic ye-enamel kwintsimbi etyhidiweyo

I-cookware ye-enamel-coated cast iron cast yenziwe ngokubunjwa okucacileyo kwezigaba zentsimbi, kuquka i-ferrite kunye ne-pearlite. I-Ferrite yinqanaba elithambileyo kunye ne-pliable, ngelixa i-pearlite idibanisa i-ferrite kunye ne-cementite, inika amandla kunye nobunzima.

Kwinkqubo yokufaka i-enamel yokugquma ukuphosa intsimbi, kubalulekile ukuqonda isakhiwo se-metallographic ukuqinisekisa ukunamathela kunye nokuqina. Esi sithuba seblogi siya kuphonononga ubume be-metallographic yentsimbi etyhidiweyo, ngokukodwa kugxininise kwiileyile ezifaka isandla ekusetyenzisweni okuyimpumelelo kwe-enamel coating.

- 1. Umaleko wesiseko: Intsimbi eNgwevu yokuCasa

Umaleko wesiseko wentsimbi esetyenziselwa ukugquma i-enamel idla ngokuba yintsimbi engwevu. Olu hlobo lwentsimbi luyaziwa ngokuba nomxholo ophezulu wekhabhoni, onika amandla agqwesileyo kunye nokumelana nokunxiba. Ikwabonakaliswe ngeeflake zayo zegraphite, ezibonelela nge-conductivity entle ye-thermal kunye nokunciphisa i-brittleness. - 2. Ukulungiswa kwe-Substrate: Ukuqhunyiswa kweSandblasting kunye nokuCoca

Umphezulu wesinyithi kufuneka ulungele ukuququzelela ukunamathela ngokufanelekileyo kwengubo ye-enamel. Oku kudla ngokubandakanya ukuqhunyiswa kwesanti ukususa nakuphi na ukungcola okanye ukungcola, okulandelwa kukucocwa ngokucokisekileyo ukuze kuqinisekiswe indawo ecocekileyo, egudileyo ukuze i-enamel ibambelele kuyo. -

Ukufakwa kwe-enamel, isinyithi esityhidiweyo kufuneka sibe nomlinganiselo olinganayo we-ferrite kunye ne-pearlite. Olu qulunqo lunikeza isiseko esomeleleyo sokuba i-enamel ibambelele kwaye iqinisekise ukuqina kwengubo. Isigaba se-ferrite sinceda ekufunxeni nasekusasazeni ukushisa ngokulinganayo, ngelixa isigaba se-pearlite songeza amandla kunye nokuchasana nokugqoka.

Ukongeza kwi-ferrite kunye ne-pearlite, ezinye izinto ezifana nekhabhoni, i-silicon, kunye ne-manganese zidlala indima ebalulekileyo. Umxholo wekhabhoni kufuneka ube yimodareyitha ukunika amandla kunye nokuthintela ukonakala. I-silicon inceda ekunamatheleni kwe-enamel, ngelixa i-manganese iphakamisa amandla onke kunye nokuqina kwentsimbi.

-

Ukushwankathela, ukubunjwa okufanelekileyo kwe-enamel-coated cast iron cookware kubandakanya umlinganiselo olinganayo we-ferrite kunye ne-pearlite, umxholo wekhabhoni ophakathi, kunye nobukho be-silicon kunye ne-manganese. Olu qulunqo luqinisekisa ukugquma kwe-enamel ehlala ixesha elide, kunye nokusabalalisa ubushushu, kunye nokusebenza okuhlala ixesha elide kwe-cookware

-

Product introduction of Changan Cast Iron Co., LTD

IindabaJan.24,2024

-

The Impact of the Leidenfrost Effect on Non-Stick Properties of Cast Iron Titanium Coated Cookware

IindabaJan.24,2024

-

Ukuphonononga ulwahlulo lweCulinary——Cast Iron Casseroles vs Regular Casseroles

IindabaJan.03,2024

-

Iworkshop yokuPakisha iLungwe ngokutsha ngeShelving kunye noGcino lwe-3D lweMpahla

IindabaDec.29,2023

-

Ukucoca imbiza ye-enamel yentsimbi esetyenzisiweyo inokwenziwa ngokufanelekileyo ngala manyathelo alandelayo:

IindabaDec.27,2023

-

Ulwakhiwo lweMetallographic ye-enamel kwintsimbi etyhidiweyo

IindabaDec.27,2023