- 150m Southwards, West DingWei Road, Nanlou Village, Changan Town, GaoCheng Area, Shijiazhuang, Hebei, China

- monica@foundryasia.com

Dec. 27, 2023 13:58 Buyela ohlwini

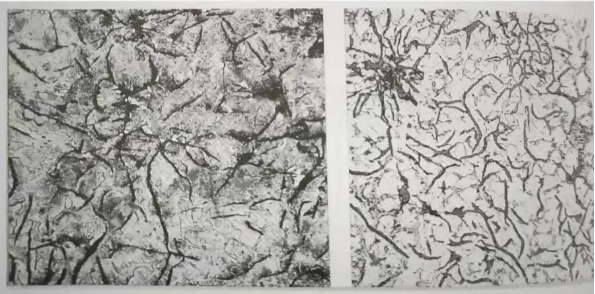

Isakhiwo se-Metallographic soqweqwe lwawo lwensimbi

I-cookware yensimbi ehlanganiswe ngoqweqwe lwawo yenziwa ngokwakhiwa okuthile kwezigaba zensimbi ekhonjiwe, okuhlanganisa i-ferrite ne-pearlite. I-Ferrite iyisigaba esithambile nesithambile, kuyilapho i-pearlite ihlanganisa i-ferrite ne-cementite, ikunika amandla nobulukhuni.

Enqubweni yokufaka i-koqweqwe lwawo lokunamathisela ekubumbeni insimbi, kubalulekile ukuqonda isakhiwo se-metallographic ukuze kuqinisekiswe ukunamathela okuhle nokuqina. Lokhu okuthunyelwe kwebhulogi kuzohlola ukwakheka kwe-metallographic yensimbi ekhonjiwe, igxile ikakhulukazi izendlalelo ezifaka isandla ekusetshenzisweni ngempumelelo koqweqwe lwawo loqweqwe lwawo.

- 1. Isendlalelo sesisekelo: I-Grey Cast Iron

Ungqimba oluyisisekelo lwe-cast iron esetshenziselwa ukunameka koqweqwe lwawo ngokuvamile luyinsimbi empunga. Lolu hlobo lwe-iron cast lwaziwa ngokuqukethwe kwalo okuphezulu kwekhabhoni, olunikeza amandla amahle kakhulu nokumelana nokugqoka. Ibuye ibonakale ngama-graphite flakes ayo, ahlinzeka nge-conductivity enhle yokushisa futhi anciphise ukuqina. - 2. Ukulungiselela I-Substrate: Ukuqhunyiswa kwesihlabathi nokuhlanza

I-cast iron surface kumele ilungiswe ukuze kube lula ukunamathela okufanele koqweqwe lwawo. Lokhu kuvame ukubandakanya ukuqhunyiswa kwesihlabathi ukuze kukhishwe noma yikuphi ukungcola noma ukungcola, okulandelwa ukuhlanzwa okuphelele ukuze kuqinisekiswe indawo ehlanzekile, ebushelelezi ukuze uqweqwe lunamathele. -

Ukuze kuhlanganiswe koqweqwe lwawo, insimbi ekhonjiwe kufanele ibe nesilinganiso esilinganiselwe se-ferrite ne-pearlite. Lokhu kwakheka kunikeza isisekelo esiqinile ukuze koqweqwe lwawo lunamathele futhi luqinisekise ukuqina koqweqwe. Isigaba se-ferrite sisiza ekumunceni nasekusabalaliseni ukushisa ngokulinganayo, kuyilapho isigaba se-pearlite sengeza amandla nokumelana nokugqoka.

Ngaphezu kwe-ferrite ne-pearlite, ezinye izakhi ezifana nekhabhoni, i-silicon, ne-manganese zidlala indima ebalulekile. Okuqukethwe kwekhabhoni kufanele kube okumaphakathi ukuze kunikeze amandla futhi kuvimbele ukuba brittleness. I-silicon isiza ukunamathela koqweqwe lwawo, kuyilapho i-manganese ithuthukisa amandla kanye nokuqina kwensimbi ekhonjiwe.

-

Ukufingqa, ukwakheka okufanelekile kwe-cookware yensimbi egqinsiwe koqweqwe lwawo kufaka phakathi isilinganiso esilinganiselwe se-ferrite ne-pearlite, okuqukethwe kwekhabhoni okumaphakathi, nokuba khona kwe-silicon ne-manganese. Lokhu kwakheka kuqinisekisa ukunamathela okuqinile koqweqwe lwawo, ngisho nokusabalalisa ukushisa, nokusebenza okuhlala isikhathi eside kwe-cookware

-

Product introduction of Changan Cast Iron Co., LTD

IzindabaJan.24,2024

-

The Impact of the Leidenfrost Effect on Non-Stick Properties of Cast Iron Titanium Coated Cookware

IzindabaJan.24,2024

-

Ukuhlola I-Culinary Divide——Cast Iron Casseroles vs Regular Casseroles

IzindabaJan.03,2024

-

Iworkshop yokupakisha ihlelwe kabusha nge-Shelving kanye ne-3D Storage for Goods

IzindabaDec.29,2023

-

Ukuhlanza ibhodwe loqweqwe lwensimbi elisetshenzisiwe kungenziwa ngempumelelo ngezinyathelo ezilandelayo:

IzindabaDec.27,2023

-

Isakhiwo se-Metallographic soqweqwe lwawo lwensimbi

IzindabaDec.27,2023