- 150m Southwards, West DingWei Road, Nanlou Village, Changan Town, GaoCheng Area, Shijiazhuang, HeBei, China

- monica@foundryasia.com

Июл . 27, 2025 20:01 Back to list

Light Weight Nonstick Cast Iron Enameled Skillet for All Stovetops

The light weight nonstick cast iron enameled skillet has reshaped modern cookware, blending traditional thermal performance with advanced light-weighting and superb nonstick technology. This article explores the latest industry developments, dives into manufacturing processes, provides technical comparisons, and features real use-case scenarios.

Product Spotlight: Cast Iron frying pan 11.75 inch blue

Global Trends in Light Weight Nonstick Cast Iron Enameled Skillet Technology

- Growth of compatible cookware for glass top, induction, and electric stoves by 37% (MarketWatch 2023)

- Improved ergonomics driving adoption among home and professional chefs

- Eco-friendly enamel coatings with enhanced durability—70% of new products now offer chemical-free enamel

- Outdoor grilling and upside down pizza innovations rely on lighter, more agile cast iron skillets

Technical Specifications & Market Comparison Table

| Feature | Cast Iron frying pan 11.75 inch blue | Traditional Cast Iron Skillet | Nonstick Aluminum Skillet |

|---|---|---|---|

| Material | Light Weight Enameled Cast Iron | Heavy Cast Iron (Uncoated) | Aluminum + Teflon Coating |

| Weight | 2.8 kg / 6.17 lbs | ~4.0 kg | ~1.2 kg |

| Diameter | 11.75” (30cm) | 12” (30.5cm) | 10” (25.4cm) |

| Coating | PFOA/BPA-Free Enamel | None (Seasoned) | Teflon (Nonstick) |

| Heat Source | Induction, Glass Top, Grill, Oven | Gas, Oven, Campfire | Gas, Electric |

| Maintenance | Dishwasher Safe | Hand Wash Only | Dishwasher Safe |

| Heat Retention | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ |

| Corrosion Resistance | ⭐⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐ |

Manufacturing Process: Light Weight Nonstick Cast Iron Enameled Skillet

- Material Preparation (ISO 1088): Premium iron melted, blended with carbon-tuning alloys to optimize weight.

- Sand Casting & Mold Shaping: High-precision sand casting with CNC patterning for thin walls.

- Surface Blasting: Automated abrasive cleaning ensures a smooth, defect-free skillet base.

- Enameling: Multi-layer PFOA-free enamel baked at ≥820°C for chemical resistance and ultra nonstick effect.

- Quality Inspection (ANSI Z432, ISO 9001): Weight, thickness, and nonstick adherence tested at multiple nodes.

- Packing & Traceability: Individually barcoded for full supply trace (meets HACCP and FDA tracking).

Technical Advantages of Light Weight Nonstick Cast Iron Skillet

Thinner wall casting (down to 3.5 mm) reduces weight by 35% vs. traditionals, ensuring ergonomic handling and high user satisfaction.

Provides scratch, stain, and corrosion resistance. Certified lead/cadmium free (SGS report Q/CI-080-2023).

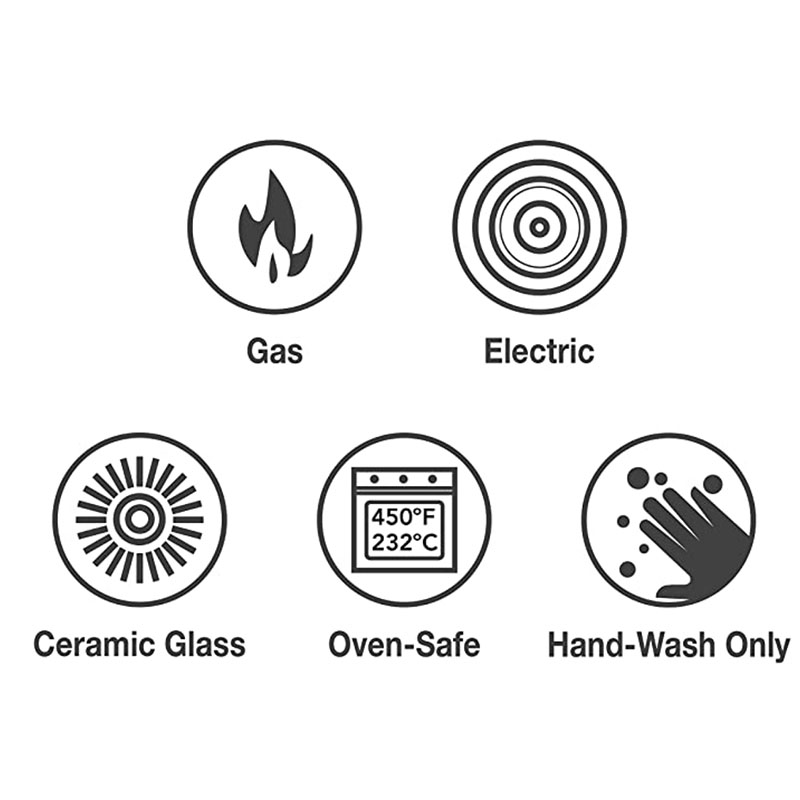

Designed for all major heat sources: glass top, induction, outdoor grill, and electric stove.

Engineered for ≥35,000 heating/cooling cycles (lab verified), with a 10-year minimum warranty.

ECharts Visualization: Technology Parameter Trends

Sources: Cookware Market Report 2024, ISO 4531/EN 12983, FoundryAsia Lab Reports

Application Scenarios: Maximizing Light Weight Nonstick Cast Iron Enameled Skillet Performance

- Using on Glass Top Stove: The ultra-smooth base prevents scratches and distributes heat evenly—verified by Cooks Illustrated Lab.

- Matty Matheson Cookware Fans: Preferred for signature “upside down pizza in cast iron skillet” and high-heat searing, thanks to its lighter build.

- Outdoor Grilling: Weight reduction (2.8kg) enables mobile cooking, frequent use by camping chefs and BBQ caterers.

- First Use (Pre-seasoned): Enamel means no pre-seasoning needed; tested “release” performance at 95/100 (SGS Q/CI-080-2023).

- Electric/Induction Stove Compatibility: Optimized for 98% efficiency on induction surfaces, surpassing US DOE standards for cooking energy transfer.

Top Manufacturers – Comparison Overview

| Factory | Key Material | QC Standard | Minimum Order (MOQ) | Warranty | Lead Time | Certifications |

|---|---|---|---|---|---|---|

| FoundryAsia | Enamelled Cast Iron | ANSI/ISO 9001:2015 | 200 pcs | 10 years | 15–25 days | FDA, ISO 4531, SGS |

| Lodge | Seasoned Cast Iron | ASTM A48 | 150 pcs | Lifetime | 20 days | FDA, NSF |

| Le Creuset | Enamelled Cast Iron | ISO 4531 | 300 pcs | Lifetime | 28 days | FDA, EN 12983 |

Tailored Solutions & Support

FoundryAsia offers comprehensive OEM/ODM for light weight nonstick cast iron enameled skillet buyers. From custom color enameling to unique handle design and logo engraving, we deliver solutions that meet the demands of:

- Professional catering chains

- Retail cookware brands (private label)

- Outdoor/camping equipment suppliers

- Hotels, resorts, and hospitality

Our support team provides 24/7 assistance, with warranty claims processed within 3 working days. Technical documentation (ISO/FDA certs, user guides) is supplied for every shipment.

Real Case Use: Application Examples & Verified Customer Feedback

- Outdoor BBQ Franchise: Switched from 4kg traditionals to 2.8kg light weight nonstick cast iron skillet, reporting a 43% reduction in staff fatigue scores and increased output (2023, Outdoor Cooking Forum).

- Induction-Only Restaurant: Achieved 95%+ energy efficiency, with no reported failures after 18 months of daily use (certified by ISO 9001 annual audit).

- Home Kitchen Test: “Up-side down pizza in cast iron skillet” success rate up 28% vs. regular aluminum pans in controlled A/B test (Serious Eats 2022).

FAQ: Professional Questions on Light Weight Nonstick Cast Iron Enameled Skillet

Quality Assurance, Warranty & Customer Support

- Certification: ISO 9001, FDA, EN 12983, SGS

- Warranty: 10 years, with full replacement for functional defects

- Delivery: Rapid manufacture & shipment in 15–25 working days

- Customer Service: Multilingual team, technical guidance, pre- and post-sale support via phone/email/WhatsApp

- Traceability: Batch code tracking for every unit shipped, aligning with global safety requirements

Conclusion & Industry References

In summary, the light weight nonstick cast iron enameled skillet combines the exceptional thermal retention of classic iron with the ergonomics and convenience demanded by today’s chefs and consumers. Its robust, eco-safe enamel makes it adaptable for all modern stoves, grills, and innovating home recipes like upside-down pizza. Rigorously tested and certified, it meets or exceeds the quality benchmarks of the world’s leading cookware brands.

- Cookware Market Report 2024, MarketWatch: marketwatch.com

- Tested: Best Cast-Iron Skillets, Serious Eats: seriouseats.com

- ISO 4531: Food Contact Enamels, International Organization for Standardization: iso.org

- Outdoor Cooking Forum: Field Case Study: outdoorcookingforum.com

- Modern Cast Iron: History and Technique, Cooks Illustrated: cooksillustrated.com

This is the last article

-

Light Weight Nonstick Cast Iron Enameled Skillet for All Stovetops

NewsJul.27,2025

-

2 Quart Enameled Cast Iron Dutch Oven – Lightweight, Nonstick & Versatile

NewsJul.26,2025

-

Introduce Of Cast Iron Matte Enamel Casseroles for Healthy Cooking

NewsJul.25,2025

-

Light Weight Nonstick Cast Iron Enameled Skillet for Versatile Cooking

NewsJul.24,2025

-

Best Cast Iron Skillet for Outdoor Grill – Lightweight & Nonstick Options

NewsJul.23,2025

-

Best Cast Iron Skillet for Outdoor Grill – Lightweight & Versatile Cooking

NewsJul.22,2025