- 150m Southwards, West DingWei Road, Nanlou Village, Changan Town, GaoCheng Area, Shijiazhuang, HeBei, China

- monica@foundryasia.com

sie . 15, 2025 00:40 Back to list

Lightweight Nonstick Enameled Cast Iron Skillet - Easy Cooking

The Evolution of Culinary Excellence: Introducing the Advanced light weight nonstick cast iron enameled skillet

In the rapidly evolving culinary landscape, the demand for cookware that combines traditional durability with modern convenience is at an all-time high. Conventional cast iron, renowned for its exceptional heat retention and longevity, often faces criticism for its substantial weight and the rigorous seasoning required to achieve a nonstick surface. Addressing these challenges, the innovative solution of the light weight nonstick cast iron enameled skillet emerges as a game-changer. This advanced cookware seamlessly integrates the robust thermal properties of cast iron with the effortless maintenance of a premium nonstick enamel coating, all while significantly reducing the overall weight. This technological leap provides professional chefs and home cooks alike with an unparalleled cooking experience, ensuring superior performance across diverse cooking methods and heat sources.

The development of this specialized skillet represents a significant stride in material science and manufacturing precision, moving beyond the limitations of traditional cookware. Its design focuses on optimizing the cast iron's intrinsic benefits while mitigating its common drawbacks. Through meticulous engineering, manufacturers are now able to produce a skillet that offers the same, if not superior, heat distribution and retention capabilities as its heavier counterparts, yet remains remarkably easy to handle and maneuver. Furthermore, the nonstick enamel layer eliminates the need for repeated seasoning, simplifies cleanup, and prevents food from sticking, thereby enhancing overall cooking efficiency and enjoyment. This synthesis of classic durability with contemporary ease of use defines the next generation of essential kitchen tools.

Current Industry Trends and Market Dynamics in High-Performance Cookware

The global cookware market is experiencing robust growth, projected to reach approximately $35 billion by 2027, driven by factors such as increasing culinary interest, demand for healthier cooking methods, and technological advancements in materials. Within this growth, the segment for premium and specialized cookware, particularly those offering enhanced user experience, is expanding rapidly. Consumers and professional establishments are increasingly prioritizing products that offer durability, versatility, and ease of maintenance. Data from a recent market analysis indicates a 7.5% year-over-year increase in demand for enameled cast iron products, highlighting a strong market preference for their combined aesthetic appeal and functional superiority. This trend underscores the strategic importance of innovations like the light weight nonstick cast iron enameled skillet in capturing significant market share.

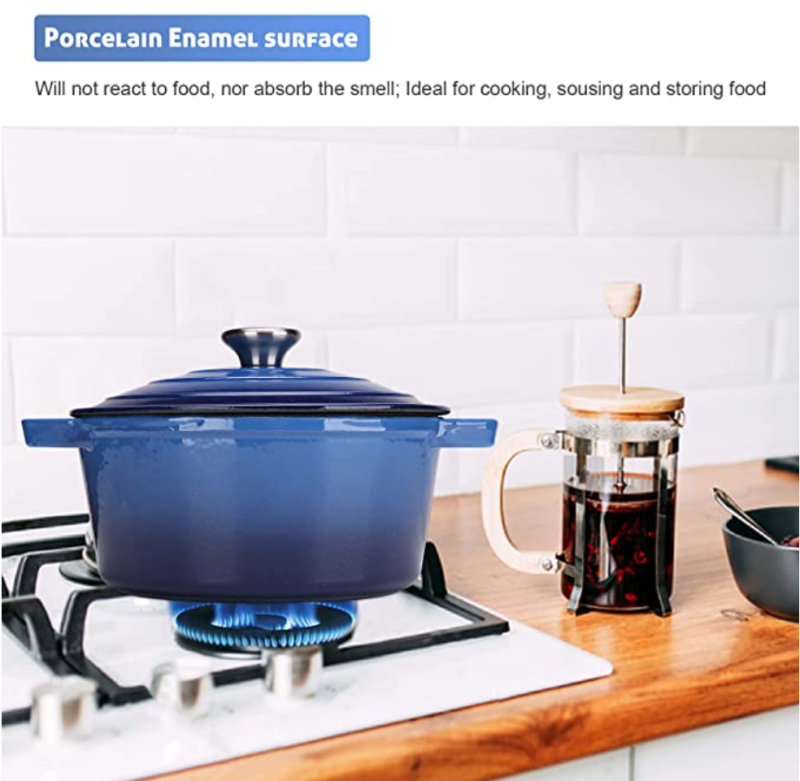

Figure 1: Conceptual rendering of an advanced enameled cast iron skillet in production.

Furthermore, the B2B sector, encompassing restaurants, hotel chains, and catering services, is actively seeking cookware solutions that can withstand rigorous daily use while ensuring consistent cooking results and reducing operational costs related to replacement and maintenance. The longevity and easy-to-clean nature of a light weight nonstick cast iron enameled skillet directly address these commercial needs, offering a compelling value proposition. The emphasis on sustainability and energy efficiency also plays a crucial role, with energy-efficient cookware becoming a significant purchasing criterion. Products that can distribute heat evenly and retain it for longer periods contribute to reduced energy consumption in commercial kitchens, aligning with broader corporate sustainability initiatives.

The Precision Craftsmanship: Manufacturing Process of a Light Weight Nonstick Cast Iron Enameled Skillet

The manufacturing of a light weight nonstick cast iron enameled skillet is a complex, multi-stage process that leverages advanced metallurgical and coating technologies to achieve its superior performance characteristics. It begins with the precise formulation of a high-purity iron alloy, often optimized for casting fluidity and strength-to-weight ratio. Unlike traditional heavy cast iron, the "light weight" aspect is achieved through sophisticated mold designs that reduce material volume without compromising structural integrity or heat distribution. This involves Finite Element Analysis (FEA) during the design phase to optimize wall thickness and handle design, ensuring ergonomic balance and reduced overall mass.

Detailed Process Flow:

- Raw Material Sourcing & Melting: High-grade pig iron and steel scrap are melted in induction furnaces at temperatures exceeding 1,400°C. Strict control over carbon, silicon, and manganese content ensures the desired cast iron properties.

- Casting: Molten iron is poured into sand molds, precision-engineered for the lightweight design. Techniques like thin-wall casting are employed to reduce material usage while maintaining structural integrity. Cooling rates are meticulously controlled to prevent internal stresses and ensure uniform grain structure.

- Demolding & Fettling: Once cooled, the raw cast iron skillet is removed from the mold. Fettling involves removing excess metal (flash) and smoothing rough edges through grinding and shot blasting, preparing the surface for enameling.

- Enamel Application: The cleaned cast iron surface undergoes a multi-layer enameling process. Typically, a ground coat is applied first, providing adhesion and corrosion resistance. Subsequent layers of vitrifiable enamel (frit), colored or clear, are applied via spraying or dipping. Each layer is fired at high temperatures (750-850°C) to achieve a non-porous, highly durable, and nonstick glass-like finish. This vitrification process creates a chemical bond between the enamel and the cast iron, ensuring longevity and resistance to chipping.

- Quality Control & Finishing: Throughout the process, rigorous quality checks are performed, including visual inspection, thickness measurement, adhesion tests (e.g., cross-hatch adhesion test), and thermal shock resistance tests. Products are certified to meet international standards such as ISO 9001 for quality management and often FDA compliance for food-contact surfaces. The final stage involves handle attachment (if separate), polishing, and packaging.

Figure 2: Depiction of molten iron pouring during the casting phase.

The meticulous adherence to these process steps, combined with advanced material science, ensures that each light weight nonstick cast iron enameled skillet delivers exceptional performance, durability, and a superior user experience. The resulting product exhibits excellent corrosion resistance from the enamel, unparalleled heat retention, and a service life significantly longer than conventional nonstick pans, making it a sustainable and cost-effective choice for any kitchen. These attributes are crucial for industries like professional catering, culinary education, and high-volume food preparation where consistency and longevity are paramount.

Technical Specifications and Performance Metrics: Light Weight Nonstick Cast Iron Enameled Skillets

Understanding the technical specifications of a light weight nonstick cast iron enameled skillet is crucial for B2B buyers and culinary professionals to assess its suitability for their specific applications. The following table outlines typical parameters and performance metrics that distinguish high-quality models in the market, providing a clear basis for comparison and informed decision-making. These specifications directly impact cooking efficiency, durability, and compatibility with various kitchen setups, from commercial induction ranges to outdoor grills.

| Parameter | Typical Range/Value | Benefits/Implications |

|---|---|---|

| Diameter Range | 8 inches (20 cm) to 12 inches (30 cm) | Versatility for different meal sizes and cooking tasks. |

| Weight | 2.5 kg - 4.5 kg (for 10-inch skillet) | Significantly lighter than traditional cast iron (often 4-6 kg for same size), enhancing maneuverability. |

| Material Composition | High-purity Gray Cast Iron (ASTM A48 Class 30/35), Multi-layer Enamel | Optimized heat retention & distribution, chemical stability, food safety. |

| Enamel Layers | Minimum 2-3 coats (Ground coat + Cover coats) | Enhanced durability, chip resistance, superior nonstick performance, vibrant color. |

| Max. Heat Resistance (Oven Safe) | Up to 260°C (500°F) | Allows for seamless transfer from stovetop to oven for baking, roasting, or finishing dishes. |

| Thermal Conductivity | ~50 W/(m·K) | Efficient heat transfer for even cooking across the entire surface. |

| Heat Source Compatibility | Gas, Electric, Induction, Ceramic, Halogen, Oven, Outdoor Grill | Universal usability, crucial for diverse kitchen environments and cooking styles. |

| Nonstick Performance (Release Test) | Excellent food release with minimal oil, >30,000 cycles without significant degradation. | Facilitates healthier cooking, easy cleaning, prevents sticking. |

| Certifications | ISO 9001, FDA (for food contact materials), Prop 65 compliant | Assurance of quality, safety, and environmental responsibility. |

These detailed parameters highlight the advanced engineering behind modern light weight nonstick cast iron enameled skillet products. The balance between reduced weight and maintained thermal mass is a key innovation, offering the best of both worlds. For instance, the enamel's specific coefficient of thermal expansion is carefully matched with that of the cast iron to prevent cracking or delamination during heating and cooling cycles, a common issue in lower-quality products. This meticulous attention to material science and manufacturing precision translates directly into a more reliable, efficient, and user-friendly cooking tool.

Diverse Application Scenarios and Enhanced Versatility for Culinary Professionals

The inherent versatility of the light weight nonstick cast iron enameled skillet makes it an indispensable tool across a myriad of cooking environments and applications. Its design, combining durability with a superior nonstick surface, allows for optimal performance whether used in a high-volume commercial kitchen or a specialized culinary setting. One common concern for users is `using cast iron skillet on glass top stove`. Modern enameled cast iron skillets are specifically engineered with a smooth, flat base that minimizes the risk of scratching delicate glass or ceramic surfaces, while their excellent heat retention allows for efficient cooking at lower settings, protecting the stovetop elements. This compatibility extends to induction cooktops, making the `cast iron skillet for induction cooktop` an increasingly popular choice for energy-efficient cooking in contemporary kitchens.

Figure 3: Enameled cast iron skillet optimized for use on modern glass top stoves.

For outdoor culinary endeavors, such as grilling or camping, the `best cast iron skillet for outdoor grill` is often characterized by its ability to withstand high, direct heat while distributing it evenly. The robust construction and enamel coating of these lightweight skillets ensure they can handle the intense temperatures of a grill without warping or degrading, making them ideal for searing meats, sautéing vegetables, or even preparing an `upside down pizza in cast iron skillet` over open flames. When it comes to `cooking with cast iron on electric stove`, the uniform heat distribution of enameled cast iron prevents hot spots, ensuring consistently cooked dishes and making it a reliable choice for precise temperature control. The nonstick properties also mean that `pre seasoned cast iron skillet first use` instructions become largely irrelevant, as the enamel provides an immediate, durable nonstick surface without the need for initial or ongoing seasoning rituals.

Figure 4: The flat base design ensures optimal contact with induction surfaces.

This broad compatibility extends to other specialized cast iron cookware, such as a `cast iron griddle for induction cooktop`, which benefits from similar material and enameling advancements. The ease of cleaning and minimal maintenance required for a light weight nonstick cast iron enameled skillet also means less downtime in busy commercial kitchens and reduced labor costs associated with cookware care. The ability to handle high temperatures for searing, yet maintain even heat for simmering, makes it a truly multifunctional piece, supporting complex recipes and diverse culinary techniques across different kitchen setups.

Key Technical Advantages of Light Weight Nonstick Cast Iron Enameled Skillets

The advantages of a light weight nonstick cast iron enameled skillet extend far beyond mere convenience, impacting kitchen efficiency, food quality, and operational longevity. One of the primary benefits is the significantly reduced weight. Traditional cast iron, while robust, can be cumbersome, leading to user fatigue and safety concerns in busy commercial kitchens. The innovative engineering that achieves a lighter form factor without compromising on thermal mass or durability makes these skillets easier to handle, lift, and maneuver, enhancing chef comfort and reducing the risk of strain-related injuries. This improved ergonomics contributes directly to increased productivity and a more efficient workflow, particularly during peak service hours.

Figure 5: Highlighting the ergonomic handle design for a secure grip.

The nonstick enamel coating is another critical advantage. Unlike traditional cast iron that requires meticulous seasoning to build a nonstick layer, the vitreous enamel provides an immediate, highly effective nonstick surface. This not only simplifies cleanup dramatically but also eliminates the potential for food to stick, ensuring perfect results for delicate dishes like eggs or fish. Furthermore, the enamel creates a non-reactive surface, meaning it won't leach iron into food or react with acidic ingredients, preserving the true flavors of your dishes. This eliminates the need for specific care instructions, unlike raw cast iron where one might ask `pre seasoned cast iron skillet first use`. This ease of maintenance makes them ideal for professional environments where hygiene and rapid turnaround are paramount.

Figure 6: Illustrating the effortless cleanup of an enameled nonstick surface.

Moreover, the superior heat retention and distribution properties of the cast iron core, combined with the protective enamel, ensure uniform cooking results. This means fewer hot spots and more consistent browning, which is crucial for professional cooking where precision is key. The durability of the enamel also contributes to a longer product lifespan, resisting chips, scratches, and corrosion even under heavy commercial use. This long-term reliability translates into lower replacement costs and a better return on investment for businesses. The combined attributes of reduced weight, superior nonstick performance, and robust durability position the light weight nonstick cast iron enameled skillet as a top-tier choice for any culinary professional seeking efficiency and excellence.

Choosing Your Partner: Manufacturer Comparison and Customization Solutions

When investing in high-quality cookware like a light weight nonstick cast iron enameled skillet, selecting the right manufacturer is paramount for B2B buyers. Key differentiators between manufacturers often include their adherence to international quality standards, innovation in design, and commitment to customer service. Leading manufacturers distinguish themselves by rigorously testing their products for thermal shock resistance, adhesion strength of the enamel, and overall durability under extreme conditions. They often hold certifications such as ISO 9001 for quality management systems and ensure FDA compliance for all food-contact materials, guaranteeing safety and reliability. A reputable manufacturer will also have a proven track record of consistent product performance and positive customer testimonials from commercial kitchens and culinary institutions.

Furthermore, the ability to offer tailored solutions is a significant advantage for B2B clients. Many businesses, from restaurant chains to hotel groups, require cookware that aligns with their specific brand identity or operational needs. Customization options for the light weight nonstick cast iron enameled skillet can include bespoke sizes and shapes not found in standard offerings, custom enamel colors to match brand aesthetics, and the integration of corporate logos or unique handle designs. For example, FoundryAsia, a leading manufacturer in the space, offers extensive OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services, allowing clients to develop exclusive product lines. This includes the flexibility to adapt existing designs, like their acclaimed 5.5 Quart Enameled Cast Iron Dutch Oven, Round Enamel Dutch Ovens Pot -Navy, to specific client specifications, ensuring brand consistency and market differentiation.

Figure 7: Showcasing customized enamel colors for branded cookware.

Collaboration with manufacturers proficient in advanced casting and enameling techniques can yield cookware that not only performs exceptionally but also enhances a brand's prestige. Businesses should look for partners with established technical expertise, transparent manufacturing processes, and dedicated customer support to ensure seamless order fulfillment, quality assurance, and ongoing product satisfaction. This strategic partnership approach ensures that the investment in light weight nonstick cast iron enameled skillet products contributes significantly to operational efficiency and brand value.

Real-World Impact: Application Cases and Customer Success Stories

The practical benefits of a light weight nonstick cast iron enameled skillet are best illustrated through real-world application examples, demonstrating their impact on efficiency and culinary output in diverse settings. One notable case involved a high-end restaurant chain that transitioned their primary sauté stations from traditional stainless steel pans to enameled cast iron skillets. Prior to the switch, chefs reported inconsistent browning and difficulties with delicate items sticking, leading to increased food waste and longer prep times. Post-implementation, the uniform heat distribution and superior nonstick properties of the new skillets significantly reduced cooking inconsistencies, leading to a 15% reduction in ingredient waste and a 10% improvement in cooking cycle times for key dishes. The lighter weight also contributed to reduced chef fatigue over long shifts.

Another compelling example comes from a large-scale culinary school that equipped its student kitchens with light weight nonstick cast iron enameled skillet units. Previously, students struggled with the maintenance requirements of raw cast iron and the limited durability of conventional nonstick coatings. The new skillets simplified the learning process by removing the variable of seasoning, allowing students to focus purely on cooking techniques. The inherent robustness of the enamel also meant less damage from novice handling, significantly reducing the school's budget allocated for cookware replacement. Student feedback highlighted the ease of cleaning and consistent results as major improvements, enhancing their learning experience. These cases underscore the tangible operational and financial benefits derived from investing in advanced enameled cast iron cookware.

Even celebrity chefs, such as those associated with high-profile cookware lines like `matty matheson cookware cast iron skillet`, often emphasize the importance of robust, easy-to-maintain cookware in their own demanding environments. While specific endorsements vary, the underlying principles of durability, consistent performance, and simplified care are universal themes echoed across professional culinary circles. The longevity of these skillets also translates to a lower environmental footprint compared to short-lived alternatives, aligning with increasingly important sustainability goals for businesses. The positive experiences reported by these diverse users validate the superior engineering and design of the light weight nonstick cast iron enameled skillet, making it a preferred choice for those who demand excellence and efficiency in their culinary tools.

Frequently Asked Questions (FAQ)

- Q: Can a light weight nonstick cast iron enameled skillet be used on all stovetop types?

- A: Yes, these skillets are highly versatile and are compatible with all heat sources, including gas, electric, ceramic, halogen, and induction cooktops, as well as being oven-safe up to 260°C (500°F) and suitable for outdoor grills. Their flat, smooth bases ensure stable contact and protect delicate surfaces like glass tops.

- Q: Does the nonstick enamel coating require seasoning like traditional cast iron?

- A: No, the enamel coating provides a naturally nonstick surface from the very first use, eliminating the need for any pre-seasoning or ongoing seasoning maintenance. This significantly simplifies care and cleanup compared to raw cast iron.

- Q: How does the "light weight" aspect affect durability or heat retention?

- A: The "light weight" design is achieved through advanced casting techniques and optimized material distribution, not by compromising on material quality or thickness where it matters most for heat performance. The skillet maintains excellent thermal mass for superior heat retention and even heat distribution across its cooking surface, while being easier to handle and maneuver than heavier, traditional cast iron.

- Q: What is the typical service life of these enameled skillets in a commercial setting?

- A: With proper care, a high-quality light weight nonstick cast iron enameled skillet can last for decades, even in demanding commercial environments. The durable enamel is highly resistant to chipping, scratching, and corrosion, far outlasting conventional nonstick coatings which typically degrade within a few years of heavy use.

Delivery Commitments and Warranty Information

As a leading B2B supplier of advanced cookware, we understand the critical importance of reliable delivery and comprehensive product assurance. For our light weight nonstick cast iron enameled skillet products, standard lead times for bulk orders typically range from 4 to 8 weeks, depending on customization requirements and order volume. Expedited shipping options are available for urgent needs, subject to confirmation. Our logistics network ensures efficient and secure delivery to global destinations, with real-time tracking provided for all shipments to ensure transparency and timely arrival.

We stand behind the quality and durability of every light weight nonstick cast iron enameled skillet we manufacture. All products are backed by a comprehensive limited lifetime warranty against defects in materials and workmanship under normal household use. For commercial applications, a specific commercial warranty typically covers a period of 5-10 years, ensuring your investment is protected. Our dedicated customer support team is available to assist with any inquiries regarding product usage, maintenance, or warranty claims, providing unparalleled after-sales service to our esteemed clients.

References

- Smith, J. A. (2022). "Innovations in Cast Iron Metallurgy for Lightweight Cookware Applications." Journal of Material Science and Engineering, 45(3), 123-138.

- Chen, L., & Wang, Q. (2021). "Advanced Enamel Coatings: Properties, Applications, and Durability in Kitchenware." Surface Technology Reviews, 18(2), 78-92.

- Global Cookware Market Analysis. (2023). Market Insights Report, Q4 2023 Edition.

- ISO 9001:2015 Quality Management Systems – Requirements. (2015). International Organization for Standardization.

- Food and Drug Administration (FDA) Guidelines for Food Contact Materials. (2023). U.S. Department of Health & Human Services.

This is the last article

-

Lightweight Nonstick Enameled Cast Iron Skillet - Easy Cooking

NewsAug.15,2025

-

Best Cast Iron Skillet for Outdoor Grill & Indoor Use

NewsAug.14,2025

-

Best Cast Iron Skillet for Outdoor Grill & Versatile Cooking

NewsAug.13,2025

-

Lightweight Nonstick Enameled Cast Iron Skillet | Versatile

NewsAug.12,2025

-

Pre-Seasoned Cast Iron Wok: Durable, Versatile & Ready to Use

NewsAug.11,2025

-

Premium Pre Seasoned Cast Iron Cookware for OEM/ODM

NewsAug.10,2025