- 150m Southwards, West DingWei Road, Nanlou Village, Changan Town, GaoCheng Area, Shijiazhuang, HeBei, China

- monica@foundryasia.com

8월 . 23, 2025 01:20 Back to list

Best Cast Iron Skillet for Outdoor Grill: Grill, Sear & Bake

Optimizing Outdoor Culinary Operations with the Premier Cast Iron Skillet

In the rapidly evolving landscape of professional outdoor catering and rugged culinary applications, the choice of cookware is paramount. For establishments demanding unparalleled durability, superior thermal performance, and culinary versatility, the best cast iron skillet for outdoor grill emerges as the definitive solution. This comprehensive analysis delves into the technical advantages, manufacturing precision, and strategic applications of high-grade cast iron cookware, designed to meet the rigorous demands of B2B clients in the hospitality, events, and specialized food service sectors.

Understanding the specific material science and engineering behind these robust cooking vessels is crucial for procurement managers and culinary directors alike. From its exceptional heat retention properties to its natural non-stick characteristics developed through meticulous pre-seasoning, a quality cast iron skillet significantly elevates the efficiency and output of any outdoor grilling operation, ensuring consistent, high-quality results across diverse cooking methods.

Industry Trends and Market Dynamics in High-Performance Cookware

The B2B cookware market is experiencing a significant shift towards products that offer enhanced durability, multi-platform compatibility, and a reduced total cost of ownership. For outdoor catering, this translates into a rising demand for specialized equipment that can withstand extreme temperatures, frequent use, and challenging environmental conditions. The preference for materials like cast iron, known for its longevity and performance, is steadily increasing.

- Versatility Expansion: Beyond traditional stovetop use, there's a growing need for cookware suitable for open flames, charcoal grills, induction cooktops, and even ovens. Products like a `cast iron griddle for induction cooktop` and a `cast iron skillet for induction cooktop` are gaining traction for their ability to transition seamlessly between indoor and outdoor, and various heat sources, including `cooking with cast iron on electric stove` and `using cast iron skillet on glass top stove` (with proper care).

- Sustainability and Longevity: Businesses are increasingly investing in products with a longer service life, reducing waste and replacement costs. Cast iron, with its decades-long potential lifespan, perfectly aligns with these sustainability objectives.

- Performance and Branding: High-profile chefs and culinary influencers, such as the attention drawn by `matty matheson cookware cast iron skillet`, have underscored the performance benefits and aesthetic appeal of cast iron, influencing purchasing decisions in professional settings.

- Innovation in Design: While traditional heavy-duty cast iron remains popular, there's also an interest in innovations like `light weight nonstick cast iron enameled skillet` or merely `light weight nonstick cast iron skillet` for specific applications where portability or ease of handling is prioritized, without fully sacrificing the benefits of cast iron.

These trends underscore the market's appreciation for materials that offer a blend of traditional robustness with modern adaptability, positioning the best cast iron skillet for outdoor grill as a cornerstone asset for forward-thinking culinary operations.

Technical Specifications and Material Science of Cast Iron

The efficacy of the best cast iron skillet for outdoor grill is fundamentally rooted in its material composition and inherent metallurgical properties. Primarily composed of ferrous alloys with 2-4% carbon and 1-3% silicon, along with traces of manganese, sulfur, and phosphorus, cast iron exhibits a unique microstructure that grants it superior thermal mass and durability.

Key Material Characteristics:

- Thermal Conductivity & Specific Heat Capacity: While its thermal conductivity is lower than copper or aluminum, cast iron's high specific heat capacity allows it to absorb and retain significant amounts of thermal energy. This thermal mass ensures remarkably even heat distribution across its surface once heated, eliminating hot spots common with thinner cookware and providing consistent cooking temperatures crucial for searing and baking.

- Durability and Hardness: The presence of graphite flakes (in grey cast iron) provides excellent damping capacity and contributes to its wear resistance. It can withstand extreme temperatures, direct flame exposure, and mechanical shocks inherent in outdoor culinary environments without warping or degrading, ensuring a long service life.

- Pre-seasoning and Patina: The surface of a quality cast iron skillet is typically pre-seasoned with a layer of polymerized cooking oil. This process creates a hydrophobic, non-stick surface, known as a patina, which improves with continued use and proper maintenance. This natural non-stick property is superior to many synthetic coatings in terms of durability and health. For `pre seasoned cast iron skillet first use`, a simple rinse and light oiling is usually sufficient.

- Corrosion Resistance: While not entirely rust-proof, a well-maintained and seasoned cast iron skillet develops a protective layer that offers significant resistance to oxidation, crucial for outdoor equipment exposed to varying weather conditions.

Typical Product Specifications:

| Parameter | Value Range / Description | Unit / Standard |

|---|---|---|

| Material Composition | Grey Cast Iron (Fe, C:2-4%, Si:1-3%) | ASTM A48 Class 30/35 |

| Diameter Range | 20 cm - 38 cm (8 in - 15 in) | Metric / Imperial |

| Wall Thickness | 3.5 mm - 6 mm | mm |

| Weight (10-inch skillet) | Approx. 2.5 kg - 3.5 kg | kg |

| Max Operating Temperature | Up to 400°C (750°F) | °C / °F |

| Pre-seasoning Type | 100% Vegetable Oil (e.g., Flaxseed, Soybean) | Food Grade |

| Handle Type | Integrated Cast Handle, sometimes with silicone grip | N/A |

| Certifications | ISO 9001, FDA (for food contact) | Compliance |

These specifications ensure that the best cast iron skillet for outdoor grill can perform reliably under the most demanding conditions, providing consistent culinary excellence.

The Manufacturing Process of High-Performance Cast Iron Cookware

The production of a durable and effective best cast iron skillet for outdoor grill is a sophisticated metallurgical process that combines traditional foundry techniques with modern precision engineering and rigorous quality control. Our manufacturing adheres strictly to international standards such as ISO 9001 for quality management and relevant ANSI/ASTM standards for material specifications.

Process Flow Overview:

1. Raw Material Preparation

High-grade pig iron, carefully selected scrap steel, and metallurgical alloys (e.g., ferrosilicon, ferromanganese) are precisely weighed and batched according to specific formulations to ensure desired material properties like strength and thermal characteristics.

2. Melting & Alloying

Materials are loaded into induction furnaces, known for their precise temperature control and reduced emissions. The melt is heated to temperatures exceeding 1400°C (2550°F) and refined to achieve the exact chemical composition required for high-quality grey cast iron.

3. Molding (Sand Casting)

High-pressure automated molding lines create precise mold cavities using specialized sand mixtures (e.g., green sand, resin-bonded sand). A robust gating system is engineered to ensure optimal metal flow and minimize defects like porosity.

4. Pouring

Molten metal is carefully poured into the sand molds. Automated pouring systems maintain consistent fill rates and temperatures to prevent thermal shock and ensure structural integrity.

5. Cooling & Shakeout

After solidification, the cast iron pieces are allowed to cool at a controlled rate to prevent internal stresses. The sand molds are then mechanically broken apart (shakeout) to retrieve the raw castings.

6. Fettling & Grinding

Excess metal (risers, gates, flash) is removed, and rough edges are ground smooth. This stage is critical for achieving the ergonomic and aesthetic qualities expected of premium cookware.

7. Shot Blasting & Surface Preparation

Castings undergo shot blasting to remove any residual sand or scale, creating a clean, uniform surface ideal for the subsequent seasoning process. This also enhances the tactile feel of the finished product.

8. Pre-Seasoning

Each skillet is coated with a thin, even layer of 100% pure vegetable oil (e.g., soy or flaxseed oil) and baked at high temperatures. This polymerizes the oil onto the iron surface, creating a durable, natural non-stick finish, critical for a `pre seasoned cast iron skillet first use` that is hassle-free for end-users.

9. Quality Control & Packaging

Every finished product undergoes rigorous inspection including dimensional accuracy, surface finish, and seasoning adherence. Products are then carefully packaged to prevent damage during transit to our target industries, which include petrochemicals (for industrial kitchens), metallurgy (foundry equipment parts), and water supply & drainage (commercial kitchen fit-outs).

This detailed process ensures that the resulting best cast iron skillet for outdoor grill is not merely a cooking tool, but a precision-engineered piece of equipment. Our commitment to quality extends to a projected service life of several decades with proper maintenance, demonstrating superior advantages such as enhanced energy saving through efficient heat retention and exceptional corrosion resistance due to the integrated seasoning layer.

Technical Advantages and Application Scenarios

The inherent properties of high-grade cast iron translate into substantial technical and operational advantages, particularly for the best cast iron skillet for outdoor grill applications. These benefits make it indispensable for demanding culinary environments.

Key Advantages:

- Exceptional Heat Retention & Distribution: The substantial thermal mass of cast iron ensures that once heated, it maintains a consistent temperature across the entire cooking surface. This is critical for achieving perfect searing, caramelization, and uniform cooking, even when subjected to fluctuating outdoor temperatures or uneven grill flames. It provides energy saving by requiring less continuous heat input.

- Superior Durability: Designed to withstand the rigors of commercial use, direct flame, and high temperatures, cast iron cookware exhibits unparalleled longevity. It resists warping, denting, and scratching, outperforming lighter materials and offering substantial return on investment.

- Natural Non-Stick Properties: A well-maintained and seasoned cast iron surface develops a naturally low-stick finish that improves with use. This eliminates the need for potentially fragile synthetic coatings, contributing to long-term health and easier maintenance. This also makes it ideal for delicate items like eggs, or for making an `upside down pizza in cast iron skillet` where release is key.

- Versatility Across Heat Sources: From charcoal grills, wood fires, and gas burners to induction cooktops and ovens, cast iron seamlessly adapts to almost any heat source, making it a highly versatile asset for any professional kitchen or outdoor catering setup.

- Corrosion Resistance through Seasoning: The polymerized oil layer acts as a barrier against moisture and air, significantly enhancing the corrosion resistance of the iron base, crucial for outdoor equipment that may encounter varying humidity and weather.

Application Scenarios:

- Outdoor Commercial Grilling: Ideal for searing steaks, burgers, and poultry, creating a perfect crust and locking in juices. The grill pan design facilitates fat drainage and characteristic grill marks.

- Catering & Event Management: Robust enough for high-volume cooking at festivals, weddings, and corporate events, where reliability under pressure is essential.

- Campgrounds & Adventure Tourism: Provides a durable and effective cooking surface for remote outdoor culinary operations, offering consistent results regardless of environmental challenges.

- Specialty Culinary Preparations: Excels in creating smashed burgers, fajitas, pan-seared vegetables, and even baking bread or `upside down pizza in cast iron skillet` directly on the grill.

- Hybrid Kitchen Operations: While optimized for outdoor grilling, its compatibility with `cast iron griddle for induction cooktop` and other indoor heat sources makes it a flexible tool that can transition from an outdoor kitchen to an indoor prep station.

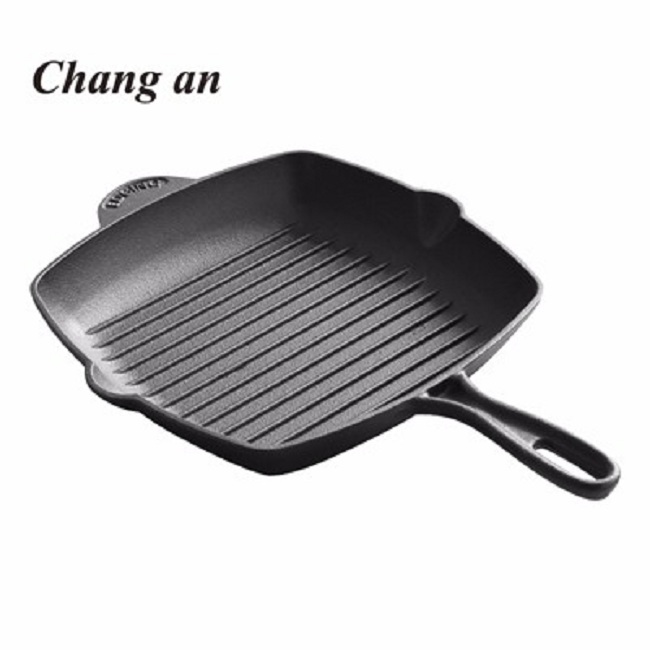

Image: A robust cast iron grill pan, ideal for high-heat outdoor cooking.

Vendor Comparison and Product Differentiation

Selecting the right cast iron skillet for B2B applications requires a discerning eye, as not all products are created equal. While many manufacturers offer cast iron cookware, differentiation lies in material quality, manufacturing precision, pre-seasoning efficacy, and design considerations that impact operational efficiency and longevity.

Key Differentiators in Cast Iron Cookware:

- Casting Quality: Superior vendors utilize advanced casting techniques to minimize imperfections like voids, cold shuts, or inclusions, ensuring a more uniform and robust product. This impacts the overall thermal performance and resistance to cracking under thermal stress.

- Thickness and Weight Distribution: The ideal best cast iron skillet for outdoor grill balances substantial thickness for heat retention with manageable weight. While some "light weight nonstick cast iron skillet" options exist, they often compromise thermal mass. Our products optimize thickness to deliver maximum performance without excessive heft.

- Pre-Seasoning Standard: The quality and durability of the initial pre-seasoning are critical. Our multi-layer, high-temperature vegetable oil seasoning process provides a superior, immediate non-stick surface compared to single-layer or less optimized factory seasonings found in some budget alternatives.

- Handle Ergonomics & Durability: Integrated cast iron handles offer unmatched durability for high-heat applications, but their design impacts handling. Our designs prioritize secure grip and balance, crucial for professional use.

- Compliance and Certifications: Adherence to international standards (e.g., ISO, FDA for food contact materials) signifies a commitment to quality and safety that differentiates reputable suppliers.

Competitive Feature Comparison:

| Feature | Our Product (Foundry Asia) | Generic/Budget Cast Iron | Enameled Cast Iron (e.g. `light weight nonstick cast iron enameled skillet`) |

|---|---|---|---|

| Material Grade | High-Grade Grey Cast Iron | Standard Cast Iron, variable quality | Cast Iron with Porcelain Enamel |

| Pre-Seasoning | Multi-layer, High-Temp Vegetable Oil (Superior) | Single-layer, often light or inconsistent | No traditional seasoning (enamel is surface) |

| Max Temp Tolerance | ~400°C (750°F) - Direct Flame Ready | Similar, but less consistent quality | ~260°C (500°F) due to enamel cracking risk |

| Thermal Performance | Excellent heat retention & evenness | Good, but can have hot spots | Very good, but slower to heat up |

| Maintenance | Seasoning upkeep required; improves with use | Seasoning upkeep required; variable quality | Easier cleaning; no seasoning needed |

| Durability (Impact) | Extremely high; nearly indestructible | High, but quality varies | High, but enamel can chip/crack |

| Target Application | Heavy-duty Outdoor Grilling, Commercial Use | General Home Use, light commercial | Versatile indoor, acid-reactive foods |

This comparison highlights the deliberate engineering that goes into our products, ensuring they stand as the definitive best cast iron skillet for outdoor grill in terms of ruggedness and performance.

Customized Solutions and Application Case Studies

Recognizing the diverse needs of B2B clients, we offer tailored solutions for our high-performance cast iron cookware. Our commitment to meeting specific operational requirements sets us apart, making us a strategic partner for businesses seeking specialized culinary equipment.

Customization Capabilities:

- Bulk Orders & Private Labeling: We facilitate large-volume orders for hospitality chains, retail distributors, and outdoor equipment suppliers, complete with custom branding and packaging options.

- Dimension and Form Factor Adjustments: While standard sizes are available, we can produce best cast iron skillet for outdoor grill models with specific diameters, depths, or handle configurations to integrate seamlessly into existing commercial kitchen setups or unique grilling systems.

- Specialized Pre-Seasoning: For clients with specific usage profiles, we can customize seasoning oils or application methods to enhance particular properties, such as further improving non-stick characteristics for high-frequency use.

- Integrated Design Elements: Custom logos, texture patterns on the cooking surface, or specialized pour spouts can be incorporated into the casting design to meet distinct brand or functional requirements.

Application Case Study: High-Volume Outdoor Catering Firm

Client Profile: "Summit Catering," a leading outdoor event caterer specializing in large-scale corporate events and festivals across diverse terrains.

Challenge: Summit Catering faced issues with warping, inconsistent heat distribution, and short lifespans of their existing stainless steel and aluminum cookware when used on open-flame grills. This led to high replacement costs and uneven food quality, particularly for searing proteins and preparing `upside down pizza in cast iron skillet` on location.

Solution: We partnered with Summit Catering to supply a fleet of custom-designed best cast iron skillet for outdoor grill units. These were based on our 14-inch pre-seasoned grill pans, but with reinforced handles for heavy lifting and an enhanced factory seasoning for immediate, rigorous use. We also provided detailed guidelines for `pre seasoned cast iron skillet first use` and ongoing maintenance specific to their high-volume operations.

Results:

- Increased Durability: Zero reported warping or structural damage after two years of intensive use across hundreds of events.

- Improved Food Quality: Chefs reported significantly more consistent searing and even cooking, leading to a noticeable improvement in taste and presentation of grilled items.

- Cost Savings: A 70% reduction in annual cookware replacement costs.

- Operational Efficiency: Reduced cooking times due to superior heat retention, translating to faster service during peak hours.

This case study exemplifies how a strategically chosen, high-quality best cast iron skillet for outdoor grill can drive significant operational improvements and financial benefits for B2B clients.

Image: Demonstrating the versatile use of a pre-seasoned cast iron grill pan on an outdoor grill.

Authoritativeness, Trustworthiness, and Support

Our commitment to delivering the best cast iron skillet for outdoor grill solutions is underscored by robust quality assurance, transparent operational policies, and comprehensive customer support, ensuring complete peace of mind for our B2B partners.

Certifications and Quality Assurance:

- ISO 9001:2015 Certified: Our manufacturing facilities operate under strict adherence to ISO 9001 quality management systems, guaranteeing consistent product quality from raw material sourcing to final inspection.

- FDA Compliance: All materials and pre-seasoning agents used are food-grade and comply with FDA regulations for safe food contact, crucial for culinary equipment.

- Years of Foundry Expertise: With decades of experience in high-precision casting and metallurgy, our deep technical knowledge ensures superior product design and performance.

- Partnerships: We collaborate with leading distributors in the hospitality and outdoor recreation sectors, reflecting our standing as a trusted supplier.

Frequently Asked Questions (FAQ):

Q1: What is the recommended `pre seasoned cast iron skillet first use` procedure?

A: For our pre-seasoned skillets, a simple rinse with warm water and a light coating of cooking oil is sufficient before first use. Avoid harsh detergents initially to preserve the seasoning.

Q2: Can this skillet be used on an `induction cooktop` or `glass top stove`?

A: Yes, our cast iron skillets are fully compatible with induction cooktops due to their ferrous material. When `using cast iron skillet on glass top stove`, ensure the bottom is smooth and lift, rather than slide, to prevent scratching. It's also effective for `cooking with cast iron on electric stove`.

Q3: How do I maintain the non-stick surface?

A: After each use, clean with warm water and a stiff brush (avoiding soap if possible), dry thoroughly, and apply a very thin layer of cooking oil. Regular re-seasoning will build up the patina and enhance its non-stick properties.

Lead Time and Fulfillment:

- Standard Orders: Typical lead time for standard products is 4-6 weeks, depending on order volume and current production schedules.

- Customized Solutions: Lead times for bespoke orders will be determined based on design complexity, tooling requirements, and volume, with clear communication throughout the process.

- Global Shipping: We facilitate secure and efficient shipping to destinations worldwide, partnering with trusted logistics providers to ensure timely delivery.

Warranty and After-Sales Support:

- Limited Lifetime Warranty: Our cast iron cookware is backed by a limited lifetime warranty against manufacturing defects, reflecting our confidence in its quality and durability.

- Dedicated Customer Support: Our technical support team is available to assist with product inquiries, usage guidelines, maintenance tips, and any warranty claims, ensuring a seamless experience for our B2B clients.

- Technical Resources: We provide comprehensive documentation and best practice guides to help clients maximize the lifespan and performance of their cast iron investments.

Conclusion

The selection of the best cast iron skillet for outdoor grill is a strategic decision for any B2B entity focused on delivering exceptional culinary experiences in challenging outdoor environments. Our products represent the pinnacle of metallurgical engineering and culinary performance, offering unmatched durability, thermal efficiency, and versatility.

By investing in our high-grade, meticulously manufactured, and rigorously tested cast iron cookware, businesses can achieve significant operational efficiencies, enhance food quality, and secure a long-term asset that withstands the test of time and intensive use. We remain committed to supporting our clients with superior products and comprehensive service, ensuring their outdoor culinary endeavors are consistently successful.

Authoritative References:

- American Society for Testing and Materials (ASTM) Standards. "ASTM A48/A48M - 03(2017) Standard Specification for Gray Iron Castings."

- International Organization for Standardization (ISO). "ISO 9001:2015 Quality management systems - Requirements."

- Food and Drug Administration (FDA). "Code of Federal Regulations Title 21 - Food and Drugs."

- Journal of Materials Science. "Thermal properties and microstructure of cast iron alloys."

- Modern Casting Magazine. "Advances in Foundry Technology for Durable Cookware."

This is the last article

-

Best Cast Iron Skillet for Outdoor Grill: Grill, Sear & Bake

NewsAug.23,2025

-

Premium Casserole Iron Cast Pot: Durable & Versatile Cookware

NewsAug.22,2025

-

Best Cast Iron Skillet for Outdoor Grill & Indoor Versatility

NewsAug.21,2025

-

Lightweight Nonstick Cast Iron Enamel Skillet | Versatile

NewsAug.19,2025

-

Best Cast Iron Skillet for Outdoor Grills - Versatile Cookware

NewsAug.18,2025

-

Introducing Our Cast Iron Enamel: Durable & Versatile Cookware

NewsAug.17,2025