- 150m Southwards, West DingWei Road, Nanlou Village, Changan Town, GaoCheng Area, Shijiazhuang, HeBei, China

- monica@foundryasia.com

Օգս . 24, 2025 01:20 Back to list

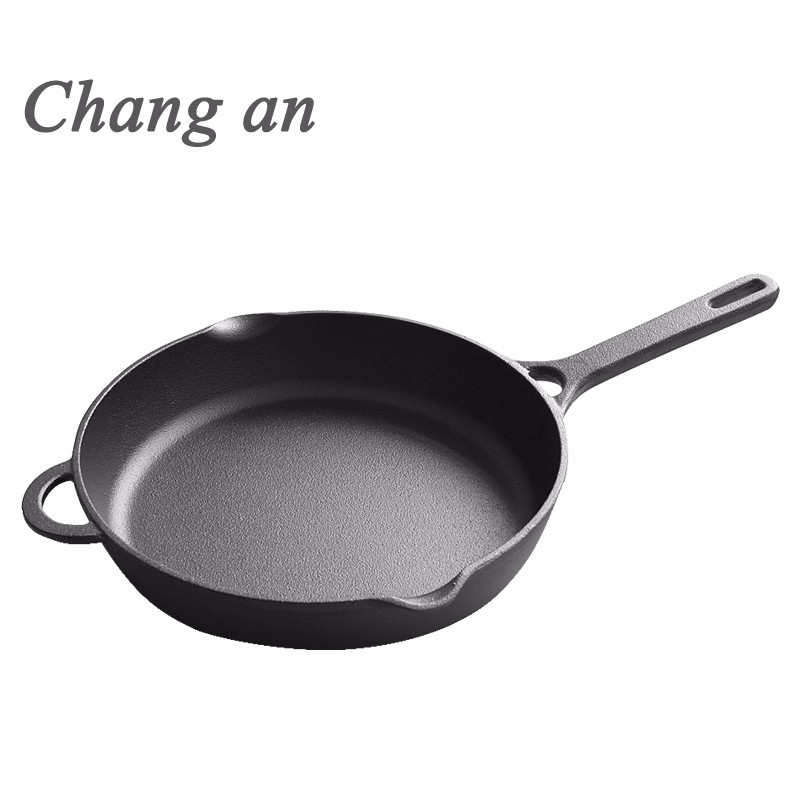

Achieve Perfect Searing: Best Cast Iron Skillet for Outdoor Grill

Industry Trends and Market Demand for High-Performance Cast Iron Cookware

The demand for durable, versatile, and high-performing cookware in both professional and consumer markets continues to expand. Particularly within the HORECA sector and among outdoor enthusiasts, the need for robust cooking solutions that withstand extreme conditions and deliver consistent results is paramount. Cast iron, known for its exceptional heat retention and durability, remains a preferred material. The market is witnessing a significant surge in interest for specialized cast iron products, with a particular focus on those optimized for diverse heat sources.

The versatility of modern cast iron extends beyond traditional stovetop use. Innovations in design and pre-seasoning techniques have made cast iron skillets indispensable for various applications, including gas grills, campfires, and even modern induction and glass-top stoves. Consumers and commercial kitchens alike seek products that can seamlessly transition from indoor cooking with a cast iron griddle for induction cooktop or a cast iron skillet for induction cooktop to rugged outdoor environments. This versatility is crucial for reducing equipment overheads and maximizing utility. The increasing popularity of outdoor grilling and experiential dining drives the specific demand for the best cast iron skillet for outdoor grill, a product category that must balance robust construction with optimal heat management for external applications.

Moreover, sustainability and longevity are key purchasing criteria for B2B clients. Cast iron products, with their multi-decade service life and minimal environmental footprint compared to disposable alternatives, align perfectly with these values. Manufacturers are focusing on advanced pre-seasoning processes to enhance user experience from the first use, minimizing the learning curve often associated with raw cast iron. The emphasis is on delivering a product that is not only high-performing but also convenient and long-lasting, catering to the exacting standards of professional chefs and large-scale catering operations.

Precision Manufacturing Process: Crafting the Optimal Cast Iron Skillet

The production of a high-quality pre-seasoned cast iron skillet for outdoor grilling involves a meticulous multi-stage manufacturing process, ensuring metallurgical integrity and superior performance. Our process adheres strictly to international quality management standards, including ISO 9001 and ANSI specifications, guaranteeing product reliability and a prolonged service life.

Process Flow Overview:

- Raw Material Selection: We commence with high-grade, virgin pig iron and carefully selected recycled ferrous scrap, ensuring a precise carbon-silicon ratio (typically 3.0-4.0% C, 1.5-3.0% Si) for optimal castability and metallurgical properties. Other alloying elements like manganese, phosphorus, and sulfur are controlled within stringent limits to prevent brittleness and improve strength.

- Melting and Alloying: Raw materials are melted in induction furnaces, allowing for precise temperature control and uniform alloying. This stage is critical for achieving the desired microstructure—typically gray cast iron (ASTM A48 Class 30-40), which offers excellent thermal conductivity and damping capacity, crucial for a best cast iron skillet for outdoor grill.

- Molding: Sand molds are prepared using advanced molding machines. These molds are designed with precision to achieve the exact dimensions and surface finish required for the skillet. Our proprietary molding techniques ensure minimal defects and uniform wall thickness.

- Casting: Molten iron is poured into the molds at a controlled temperature and rate. The casting process is carefully monitored to prevent cold shuts, porosity, and other casting defects. Rapid solidification ensures a fine grain structure, enhancing durability.

- Fettling and Grinding: After cooling, the cast iron pieces are removed from the molds. Excess metal (sprue, risers, gates) is removed through fettling. Subsequent grinding and polishing operations ensure smooth edges and a flat cooking surface, critical for efficient heat transfer and user safety. CNC machining is applied for precision finishing where necessary.

- Shot Blasting: The surfaces are shot-blasted to remove any residual sand or scale, creating an ideal profile for seasoning adherence. This enhances the longevity of the pre-seasoned layer.

- Pre-Seasoning Application: Unlike unseasoned cast iron, our products undergo a proprietary high-temperature pre-seasoning process. Multiple layers of vegetable oil (typically soybean or flaxseed oil) are baked onto the surface at temperatures exceeding 200°C. This polymerization process creates a naturally non-stick, rust-resistant surface, making the pre seasoned cast iron skillet first use experience immediately positive and user-friendly. This critical step differentiates our product significantly, offering immediate utility and enhanced corrosion resistance.

- Quality Control and Testing: Each skillet undergoes rigorous inspection, including visual checks for surface defects, dimensional accuracy measurements, and functional tests. Our products meet or exceed international standards for food contact materials (e.g., FDA requirements for inertness) and structural integrity. Service life is projected for decades under proper care, far exceeding the typical lifecycle of many other cookware types.

- Packaging: Products are carefully packaged to prevent damage during transit, ensuring they arrive in pristine condition.

Target industries for our robust cast iron cookware include the petrochemical industry (for employee catering in harsh environments), metallurgy (for high-heat applications), and the water supply & drainage sectors (for remote camp cooking). The inherent advantages in these scenarios include energy saving through superior heat retention and exceptional corrosion resistance dueated to advanced seasoning.

Technical Specifications and Performance Parameters

Understanding the intrinsic technical specifications of a cast iron skillet is crucial for B2B buyers to evaluate its suitability for specific industrial and commercial applications. Our pre-seasoned cast iron skillets are engineered to deliver consistent, high-performance cooking results under various thermal conditions.

Product Specification Table: Pre-seasoned Cast Iron Skillet

| Parameter | Specification | Measurement Unit |

|---|---|---|

| Material Composition | Grey Cast Iron (ASTM A48 Class 30-40) | N/A |

| Standard Diameter Range | 20 - 32 | cm |

| Weight Range (Approx.) | 2.5 - 5.0 | kg |

| Wall Thickness | 4.0 - 5.5 | mm |

| Pre-seasoning Type | Vegetable Oil (Multiple Polymerized Layers) | N/A |

| Max. Operating Temperature | 500+ | °C |

| Heat Retention Index (relative) | Excellent (9/10) | N/A |

| Thermal Shock Resistance | High | N/A |

| Induction Compatibility | Full | N/A |

| Hardness (Brinell) | 180-220 | HB |

| Certifications | ISO 9001, FDA Compliant for Food Contact | N/A |

The robust construction and material properties make our cast iron skillets ideal for various heat sources, including open flames, charcoal grills, ovens, and even electric or glass-top stoves. When using cast iron skillet on glass top stove, the flat, machined base ensures stable contact and efficient heat transfer without scratching, provided proper lifting techniques are used. Similarly, for cooking with cast iron on electric stove, the high thermal mass prevents hot spots and delivers incredibly even heat distribution.

Our engineering focuses on optimizing these parameters to ensure that each best cast iron skillet for outdoor grill provides superior thermal stability and cooking performance, making it a reliable asset for any professional kitchen or demanding outdoor catering setup.

Versatile Application Scenarios

The inherent durability and thermal properties of our pre-seasoned cast iron skillets make them exceptionally versatile across a multitude of professional and commercial cooking environments. From high-volume outdoor catering events to specialized culinary preparations, these skillets perform consistently.

- Outdoor Grilling and BBQ Events: As the definitive best cast iron skillet for outdoor grill, it excels in direct flame cooking, retaining and distributing heat evenly to achieve perfect searing on steaks, charring vegetables, or even preparing delicate seafood. Its robustness means it can withstand the rigors of open-flame cooking without warping or degradation.

- Professional Kitchens: Beyond outdoor use, its exceptional heat retention makes it ideal for busy restaurant kitchens. From stovetop searing to oven-finished dishes, the consistent performance contributes to culinary excellence. It's compatible with various heat sources, including professional gas ranges and induction cooktops, mirroring the functionality of a dedicated cast iron skillet for induction cooktop.

- Camping and Expedition Catering: For remote site operations, military field kitchens, or large-scale camping expeditions, the durability and multi-source compatibility of our skillets are invaluable. They can be used directly over campfires, portable gas burners, or even Dutch oven style, making them a cornerstone of rugged culinary logistics.

- Specialty Baking: The even heat distribution and ability to withstand high temperatures make it perfect for baking applications. For instance, creating an upside down pizza in cast iron skillet yields a perfectly crispy crust and evenly cooked toppings, a technique popular in artisan pizzerias and specialty bakeries.

- Culinary Demonstrations & Food Service Training: High-profile chefs and culinary institutions often feature cast iron cookware for its performance and visual appeal. Skillets associated with renowned figures like matty matheson cookware cast iron skillet, highlight the high regard for this material in professional circles, and our products meet similar standards for quality and performance.

- Industrial and Remote Site Operations: Companies in sectors like construction, mining, and oil & gas, which often operate in remote locations, rely on robust cooking equipment for their on-site catering facilities. The resilience of cast iron against harsh environments and diverse heat sources makes it an indispensable asset.

The versatility extends to compatibility with modern kitchen appliances, allowing seamless integration into diverse culinary setups. Whether it's the intense heat of an outdoor grill or the controlled environment of a professional range, our skillets are built to perform.

Technical Advantages and Performance Differentiation

Our pre-seasoned cast iron skillets offer a suite of technical advantages that position them as a superior choice for demanding B2B applications, significantly outperforming many contemporary cookware alternatives.

- Unrivaled Heat Retention and Distribution: The high thermal mass of cast iron enables it to retain heat far more effectively than aluminum or stainless steel. This property ensures exceptionally even heating across the entire cooking surface, eliminating hot spots and facilitating uniform browning and searing—critical for high-quality culinary output, especially for a best cast iron skillet for outdoor grill.

- Superior Durability and Longevity: Engineered for industrial use, our skillets are resistant to warping, denting, and scratching, even under extreme thermal cycling and mechanical stress. With proper care, they are virtually indestructible and offer a multi-decade service life, representing a significant long-term investment.

- Natural Non-Stick Properties (Pre-seasoned): The factory pre-seasoning creates a durable, non-toxic, naturally non-stick cooking surface. This eliminates the need for synthetic coatings, which can degrade over time and leach chemicals. The non-stick layer improves with use, offering superior food release and easier cleaning, a key advantage over unseasoned cast iron where the pre seasoned cast iron skillet first use benefits are immediately apparent.

- Versatility Across Heat Sources: Our skillets are compatible with virtually any heat source: open flames, charcoal grills, gas stoves, electric coils, induction cooktops, and ovens. This adaptability makes them indispensable in diverse kitchen setups, from traditional to modern, and particularly for the dynamic requirements of outdoor catering. This versatility contrasts sharply with specialized cookware like a light weight nonstick cast iron enameled skillet which, while nonstick, may have temperature limitations for enameling and different heat retention profiles.

- Enhanced Nutritional Value: Cooking in cast iron can naturally fortify food with dietary iron, offering a health benefit, especially in large-scale meal preparation where nutritional content is a concern.

- Cost-Effectiveness: While the initial investment might be higher than entry-level cookware, the unparalleled durability, long service life, and consistent performance lead to a significantly lower total cost of ownership over time, making it a strategic choice for businesses.

These technical advantages underscore why our cast iron skillets are not just cooking vessels, but vital tools that contribute to operational efficiency, product quality, and long-term value for B2B enterprises.

Vendor Comparison and Competitive Analysis

In a competitive market for professional cookware, distinguishing between manufacturers is critical. Our analysis highlights key differentiators that position our pre-seasoned cast iron skillets as a premium choice, particularly as the best cast iron skillet for outdoor grill, when compared to other industry offerings.

Comparative Analysis: Cast Iron Skillets for B2B Applications

| Feature/Parameter | Our Product (FoundryAsia) | Competitor A (Premium Brand) | Competitor B (Value Brand) |

|---|---|---|---|

| Material Grade | ASTM A48 Class 30-40 Virgin Iron | High-Grade Recycled Iron | Standard Mixed Scrap Iron |

| Pre-Seasoning Process | Multi-layer Baked Vegetable Oil (Proprietary) | Single-layer Baked Oil | Light Oil Coating (Minimal) |

| Surface Finish | CNC Machined Flat Base, Smooth Cooking Surface | Ground Finish, Slightly Textured | Rough Cast, Uneven |

| Heat Retention Uniformity | Excellent (Consistent temperature distribution) | Very Good (Minor variations) | Good (Noticeable hot/cold spots) |

| Certifications | ISO 9001, FDA Compliant, ANSI | ISO 9001 (General) | Limited (Basic Safety) |

| Warranty | Limited Lifetime (Structural Integrity) | 10-Year Limited | 1-Year Standard |

| Customization Options | Extensive (Sizes, Logos, Finishes) | Moderate (Sizes, Limited Branding) | Minimal (Standard SKUs only) |

| Target Market | B2B, Commercial, Industrial, Premium Retail | High-End Consumer, Small Business | Mass Market Consumer |

While some competitors offer options like light weight nonstick cast iron skillet variants or specialized enameling, these often come with trade-offs in heat retention, maximum temperature tolerance, or overall durability. Our focus remains on delivering the robust, high-performance cast iron experience essential for the rigorous demands of professional use. This commitment to quality and longevity, combined with our advanced manufacturing processes, ensures that our products provide unmatched value and reliability.

Customized Solutions and Application Case Studies

Recognizing the diverse needs of our B2B clientele, we offer comprehensive customization options to ensure our cast iron skillets precisely meet unique operational and branding requirements. Beyond standard SKUs, our engineering and manufacturing capabilities allow for significant adaptations.

Customization Capabilities:

- Dimension and Form Factor: From specific diameters and depths to integrated handles or specialized griddle shapes for unique grill setups, we can cast to precise specifications.

- Branding and Logos: Custom logos, serial numbers, or brand names can be incorporated directly into the casting mold or etched post-production, offering enhanced brand visibility and product traceability.

- Surface Finishes and Pre-Seasoning Variants: While our standard pre-seasoning is optimized, we can explore alternative seasoning oils or multi-stage processes to meet specific culinary demands or operational environments.

- Accessory Integration: Design and production of compatible accessories such as custom lids, trivets, or specialized cleaning tools tailored to the specific skillet design.

Application Case Studies:

A national outdoor event catering firm approached us requiring a durable and highly efficient cooking solution for their mobile kitchens. Their primary challenge was maintaining consistent high temperatures across multiple cooking stations, often exposed to varying weather conditions. They needed a product that could serve as the best cast iron skillet for outdoor grill use on propane-fired griddles and open charcoal pits.

We provided custom-designed, heavy-gauge pre-seasoned cast iron skillets (36 cm diameter) with reinforced handles for safer transport and handling in fast-paced environments. The enhanced thermal mass significantly reduced cooking times and fuel consumption, leading to a 20% increase in serving efficiency and a 15% reduction in gas usage per event, as reported by the client. The robust pre-seasoning also reduced initial prep time and maintenance.

A boutique hotel chain, committed to sustainable practices and local sourcing, sought to upgrade their kitchen equipment with long-lasting, chemical-free cookware. They needed versatile skillets compatible with their induction cooktops and occasional outdoor patio grilling events. They specifically looked for a reliable cast iron skillet for induction cooktop that could also handle direct flame.

We supplied a range of our pre-seasoned cast iron skillets, emphasizing their natural non-stick properties and multi-source compatibility. The chain appreciated the lack of PTFE/PFOA coatings and the iron fortification benefits. Their chefs reported superior searing capabilities and consistent results. The average lifespan of their previous non-stick cookware was 1-2 years; with our cast iron, they project a service life exceeding 15 years, significantly reducing their procurement waste and long-term costs.

A major mining corporation operating in a remote, harsh environment required extremely durable cookware for their camp commissary, feeding hundreds of personnel daily. The equipment needed to withstand constant heavy use, varying ambient temperatures, and be easy to maintain by rotational staff.

Our heavy-duty, commercial-grade pre-seasoned cast iron skillets were chosen for their robust construction and proven performance in challenging conditions. The inherent corrosion resistance from the seasoning and the ease of re-seasoning by staff made them ideal. The commissary manager noted a drastic reduction in cookware replacement costs and improved meal consistency due to the superior heat characteristics of the cast iron, even when cooking with cast iron on electric stove burners in their temporary kitchen setups.

Trust and Support: FAQs, Lead Times, Warranty, and After-Sales Service

At FoundryAsia, we understand that B2B partnerships are built on trust, transparency, and reliable support. We are committed to providing exceptional service from initial inquiry through the entire product lifecycle.

Frequently Asked Questions (FAQs):

A1: Our skillets are pre-seasoned and ready for immediate use. For the first use, simply rinse with warm water, dry thoroughly, and apply a thin layer of cooking oil before heating. Avoid harsh soaps initially to preserve the seasoning. Subsequent uses will further build the non-stick layer.

A2: Yes, absolutely. Our skillets are designed with a flat, precision-machined base, making them perfectly compatible with all heat sources, including induction cooktops and glass-top stoves. The flat base ensures efficient heat transfer and stability. Care should be taken to always lift, not slide, cast iron on glass-top surfaces to prevent scratching, which is a common best practice when using cast iron skillet on glass top stove.

A3: With proper care and maintenance, our cast iron skillets are designed to last for decades, often becoming heirloom pieces. Their robust construction ensures exceptional durability, making them a one-time investment for a lifetime of use.

A4: Yes, they are specifically engineered for the rigorous demands of commercial and industrial kitchens. Their superior heat retention, durability, and ease of maintenance make them ideal for high-volume cooking environments, from fine dining establishments to outdoor catering firms, including being the best cast iron skillet for outdoor grill use.

Lead Time and Fulfillment Details:

Our standard lead time for stock items is typically 2-4 weeks from order confirmation, depending on volume. For customized solutions and large-scale orders, lead times will be provided with a detailed quotation, generally ranging from 6-12 weeks to accommodate tooling and production specificities. We maintain agile manufacturing processes to ensure timely delivery and can discuss expedited options for urgent requirements.

Warranty Commitments:

We offer a Limited Lifetime Warranty on the structural integrity of our cast iron skillets against manufacturing defects, underscoring our confidence in their quality and durability. This warranty covers casting flaws, material defects, and significant structural failures under normal use and care. Details regarding warranty coverage and claims procedures are available upon request.

Customer Support Information:

Our dedicated B2B customer support team is available to assist with product inquiries, technical specifications, order placement, and after-sales service. We offer multi-channel support including phone, email, and a dedicated online portal for corporate clients. Our technical experts can provide guidance on product selection, maintenance, and optimal usage tailored to specific industry requirements.

For immediate assistance, please visit our contact page or reach out to your assigned account manager.

Conclusion

The pre-seasoned cast iron skillet from FoundryAsia represents the pinnacle of durable, high-performance cookware, specifically engineered to meet the rigorous demands of B2B and commercial applications. From its precision manufacturing through advanced casting and multi-layer pre-seasoning, to its unparalleled heat retention and versatility across all heat sources, it consistently delivers superior culinary results. As the definitive best cast iron skillet for outdoor grill, it stands ready to elevate cooking experiences in any professional setting, providing an exceptional return on investment through its longevity and reliability. We invite B2B decision-makers to explore our range and customize solutions that integrate seamlessly into their operations, backed by our commitment to quality and comprehensive support.

References

- American Society for Testing and Materials (ASTM). ASTM A48/A48M-03(2017) Standard Specification for Gray Iron Castings. ASTM International.

- International Organization for Standardization (ISO). ISO 9001:2015 Quality management systems – Requirements.

- Food and Drug Administration (FDA). Code of Federal Regulations, Title 21, Part 175 - Indirect Food Additives: Adhesives and Coatings.

- University of Illinois Urbana-Champaign. Department of Materials Science and Engineering. "Properties of Cast Iron."

- Ohio State University Extension. "Care and Use of Cast Iron Cookware."

This is the last article

-

Achieve Perfect Searing: Best Cast Iron Skillet for Outdoor Grill

NewsAug.24,2025

-

Best Cast Iron Skillet for Outdoor Grill: Grill, Sear & Bake

NewsAug.23,2025

-

Premium Casserole Iron Cast Pot: Durable & Versatile Cookware

NewsAug.22,2025

-

Best Cast Iron Skillet for Outdoor Grill & Indoor Versatility

NewsAug.21,2025

-

Lightweight Nonstick Cast Iron Enamel Skillet | Versatile

NewsAug.19,2025

-

Best Cast Iron Skillet for Outdoor Grills - Versatile Cookware

NewsAug.18,2025