- 150m Southwards, West DingWei Road, Nanlou Village, Changan Town, GaoCheng Area, Shijiazhuang, HeBei, China

- monica@foundryasia.com

srp . 29, 2025 23:40 Back to list

High-Quality Iron Dutch Oven Pot for ODM & OEM Solutions

Explore the evolution, technology, and application of iron dutch oven pot, including ODM iron dutch oven pot and OEM iron dutch oven pot, focusing on advanced manufacturing, market demand, and real-world use cases. Dive into in-depth comparisons, technical parameters, and exclusive customizable solutions for professionals seeking excellence in cast iron cookware.

Industry Trends and Market Insights

The iron dutch oven pot market has witnessed significant growth with an estimated CAGR of 5.8% (2022-2029, source), driven by the surging popularity of energy-efficient and durable cookware in both domestic and industrial environments. The global focus on sustainable manufacturing and rigorous compliance with ISO/ANSI standards further boosts the market for high-quality products such as OEM iron dutch oven pot and ODM iron dutch oven pot.

Key Technical Parameters of Iron Dutch Oven Pots

| Model | Capacity (Qt) | Material | Coating | Temperature Resistance (°C) | Weight (kg) | OEM/ODM Support | Certification |

|---|---|---|---|---|---|---|---|

| 3 Quart Enameled | 3 | Cast Iron | Porcelain Enamel | ~500 | 5.1 | Yes | ISO/ANSI/FDA |

| Classic Cast Iron | 5 | Cast Iron | Pre-seasoned | ~400 | 6.8 | Yes | ISO |

| Premium Dutch Oven | 6 | Ductile Iron | Enamel | ~550 | 7.3 | Yes | ISO/ANSI |

Detailed Manufacturing Process: 3 Quart Enameled Cast Iron Dutch Oven Pot with Lid

Manufacturing Flow Diagram:

- Raw Material: High-purity pig iron & alloying elements, ensuring mechanical strength and corrosion resistance.

- Casting: Advanced sand mold casting for impeccable finish and form accuracy.

- CNC Machining: Precision trimming of pot rims and lid interfaces.

- Enamel Coating: Three-layer vitreous enamel provides excellent non-stick and anti-corrosive properties, meeting FDA food safety requirements.

- Inspection: Each iron dutch oven pot is rigorously tested for porosity, mechanical integrity, and temperature resilience under ISO 9001 and ANSI protocols.

Technology Advantages of Iron Dutch Oven Pot

- Material Superiority: Uniform wall thickness & fine-grained cast structure provide iron dutch oven pot with robust thermal retention and even heat distribution.

- Enamel Layer: Non-reactive, durable, and compliant with food-grade FDA standards.

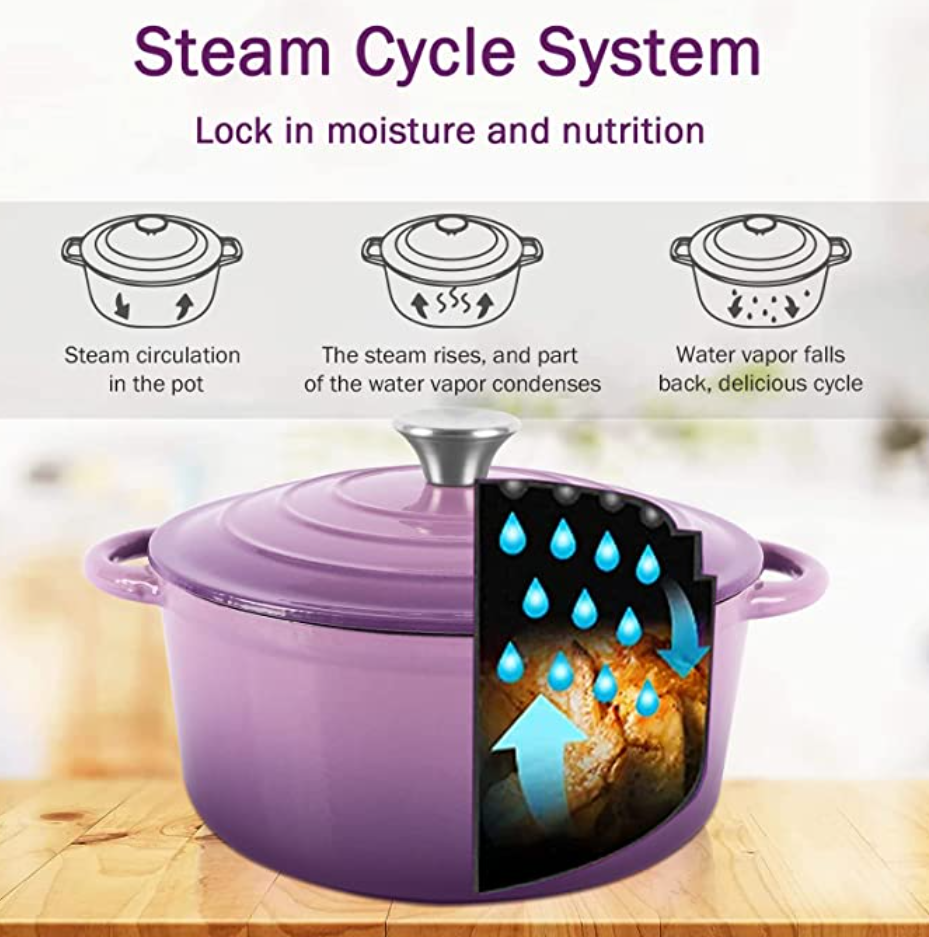

- Precision Engineering: Tight-tolerance CNC finishing ensures perfect lid fit and vapor retention crucial for braising.

- Anti-Corrosion: Multi-step enameling leads to up to 15-year resistance in acid/alkaline use (industry study).

- Life Span: Certified use cycle of over 10,000 heating/cooling cycles per ISO 7145.

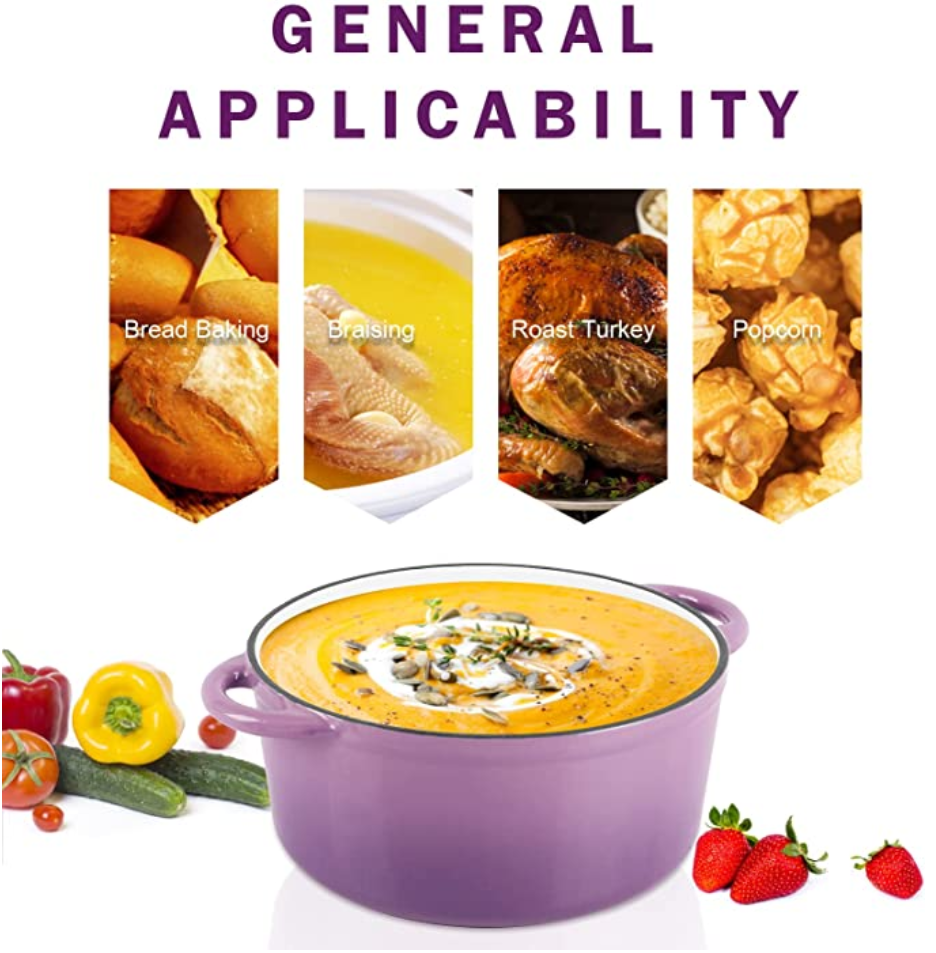

Application Scenarios and Industry Use Cases

Iron dutch oven pot products serve both household and industrial applications. In the culinary sector, these pots excel in slow-cooking, braising, and baking due to their superb thermal inertia and non-reactive surface.

- Petrochemical Industry: Laboratory vessels and test pot usage for corrosion simulation.

- Metallurgy: Pre-treatment container111s for sample analysis withstands frequent thermal cycling

- Water Supply/Drainage: Used as chemical solution holding vessels owing to their ISO 9001-certified impermeability and corrosion resistance.

- Commercial Kitchens: Constantly in use for industrial food production owing to their FDA food-grade safe coating and ease of sterilization.

- Deployed 2,800 units of oem iron dutch oven pot in production kitchens over 5 years.

- Reported 12% energy savings annually (per comparison with stainless alternatives).

- Zero corrosion claims in 60 industrial pilot plants.

- All units passed 10,000 hot-cold cycles (ISO 729 Test Protocols).

- Operator survey: 97% appreciation for cleaning ease, 89% satisfied with heat retention and flavor results.

Iron Dutch Oven Pot: Factory Comparison and Customization Solutions

| Specification | OEM Iron Dutch Oven Pot | ODM Iron Dutch Oven Pot | Standard Model |

|---|---|---|---|

| Custom Capacity | Yes | Optional | Fixed |

| Surface Finishing | Matte/Gloss, Logo, Colors | Customized by request | Standard Enamel |

| Coating Certification | FDA, ISO, LFGB | FDA, ISO, ANSI | FDA, ISO |

| MOQ | 300 pcs | 500 pcs | 100 pcs |

| Project Lead Time | 25-40 days | 40-60 days | 7-20 days |

Customization Services

- ODM iron dutch oven pot: Tailored design with patent protection, unique coating, and distinctive handle ergonomics by FoundryAsia’s R&D team.

- OEM iron dutch oven pot: Private label, bespoke logos/colors, and packaging per client specification.

Delivery, Warranty & Customer Support

- Lead Time: 25-40 days for custom iron dutch oven pot orders. Urgent/express manufacturing available.

- Warranty: 10-year warranty against warping and corrosion; full replacement policy for manufacturing defects after third-party inspection.

- After-sales Service: 24-hour technical support, operational training, spare part supplies, and global logistics coordination.

- Certifications: ISO 14001, FDA, and LFGB certified.

- Support Channels: Telephone, email, WhatsApp, WeChat. Troubleshooting videos and on-site assistance (by appointment).

Professional FAQ: Iron Dutch Oven Pot

- Q1: What is the primary material used in iron dutch oven pot manufacturing?

- A1: High-grade cast iron, featuring a high carbon content and microstructure that ensures superior thermal conduction and mechanical strength over repeated heating cycles.

- Q2: What are typical product specifications?

- A2: Standard size ranges include 3Qt, 5Qt, and 6Qt. Wall thickness: 3.8–4.2mm. Lid fit: ≤1mm gap. Oven-safe up to 500°C, compliant with ISO and FDA food contact standards.

- Q3: Describe the installation/usage standards for iron dutch oven pot in industrial sectors.

- A3: Install and operate per ANSI Z21.18 and ISO 9001 protocols; ensure uniform heating and controlled cool-down to avoid premature thermal fatigue.

- Q4: What is an OEM iron dutch oven pot?

- A4: It's a pot produced to client’s specification—logo, design, and packaging—by a manufacturer, ensuring exclusive market branding and configuration.

- Q5: How does an ODM iron dutch oven pot differ?

- A5: ODM products are designed and engineered by the manufacturer with exclusive or semi-exclusive specification and intellectual property; ideal for buyers needing unique, differentiated products.

- Q6: Which industry certifications are important?

- A6: ISO 9001 (Quality Management), ISO 14001 (Environmental Management), FDA (Food Safety), and ANSI Z21.18 (Industrial Usage Safety) are critical certifications for top-tier pots.

- Q7: What are the surface treatments available?

- A7: Options include triple enamel coating (color selection available), pre-seasoned oil finish for bare iron, and hybrid non-stick layering, all with LFGB/FDA test reports.

Customer Feedback

Factory Response: Both oem iron dutch oven pot and odm iron dutch oven pot batches passed 100% quality verification on delivery, supporting Angela’s high-volume factory with custom packaging and documentation.

Conclusion & Authoritative References

The global iron dutch oven pot segment is defined by innovation in materials, rigorous manufacturing standards, and end-to-end solutions for both home chefs and industrial clients. Trust in established certifications, factory expertise, and real-world result metrics when making sourcing decisions in this fast-evolving niche.

- Cast Iron Cookware Market Insights: ReportLinker

- Food Contact Material Regulations: U.S. FDA

- Engineering Standards: ISO 9001, ANSI

- Scientific Research: Cast Iron Corrosion Resistance (ISIJ International)

- Industry Discussions & Practitioner Reviews: Cookware Industry Forum

- Customization Trends: Cookware Manufacturing Journal

-

Best Cast Iron Skillet for Outdoor Grill – Versatile & Lightweight Options

NewsJul.30,2025

-

High-Quality Iron Dutch Oven Pot for ODM & OEM Solutions

NewsJul.29,2025

-

Best Cast Iron Skillet for Outdoor Grill – Versatile, Durable & Lightweight

NewsJul.29,2025

-

Pre Seasoned Cast Iron Skillet First Use Guide for OEM & ODM Solutions

NewsJul.29,2025

-

Premium Pre Seasoned Cast Iron Cookware for OEM & ODM Solutions

NewsJul.29,2025

-

Best Cast Iron Skillet for Outdoor Grill – Lightweight & Versatile Cooking

NewsJul.28,2025