- 150m Southwards, West DingWei Road, Nanlou Village, Changan Town, GaoCheng Area, Shijiazhuang, HeBei, China

- monica@foundryasia.com

Juil . 31, 2025 17:40 Back to list

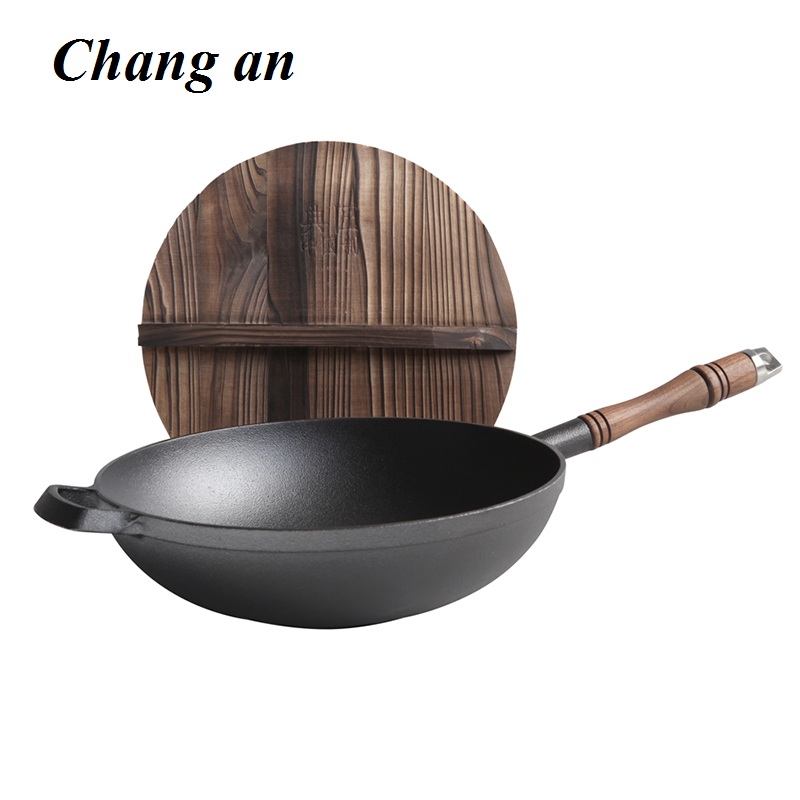

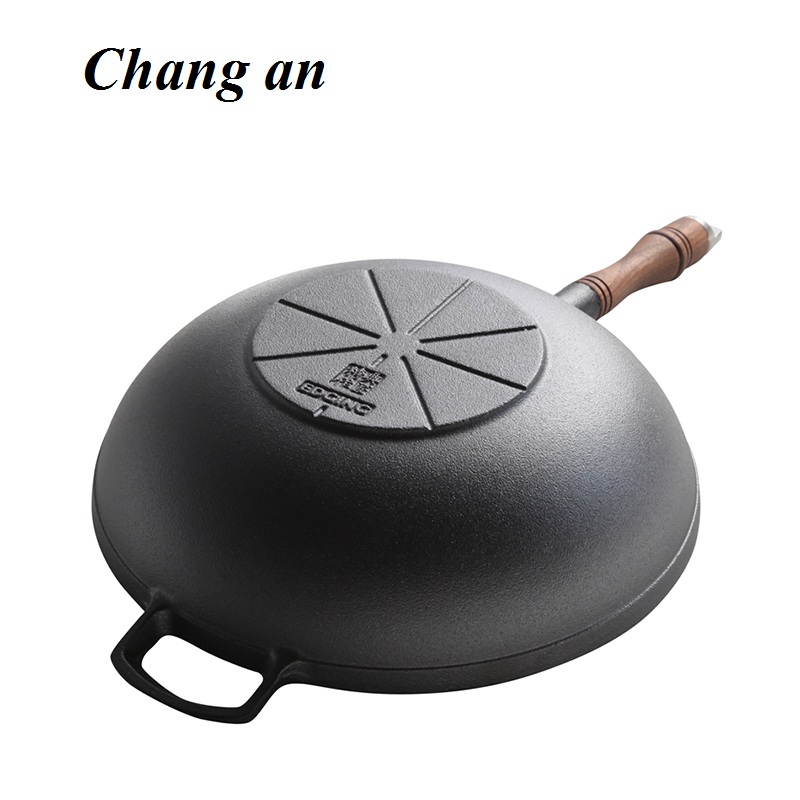

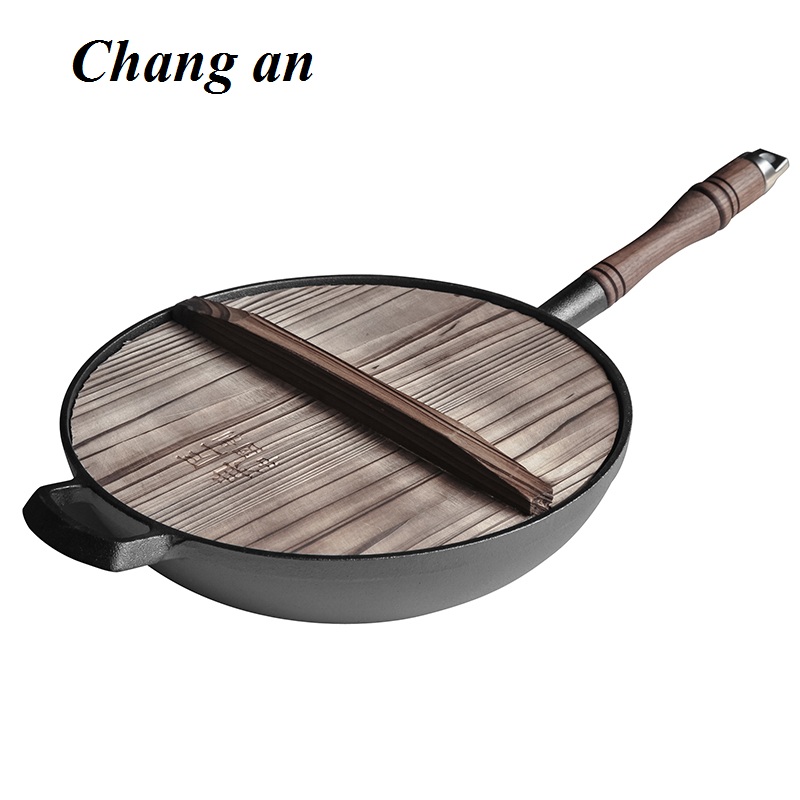

Pre-Seasoned Cast Iron Wok - Fast Heat & Durable

The demand for Pre-Seasoned Cast Iron Wok has seen significant growth globally. According to the Grand View Research report (2023), the global cast iron cookware market was valued at USD 2.7 billion in 2022 and is expected to expand at a CAGR of 6.1% from 2023 to 2030. The rising preference towards sustainable, healthy, and energy-saving cookware in both domestic and industrial kitchens is accelerating the adoption of pre-seasoned cast iron solutions.

- Surging demand from restaurants, hotels, and large-scale food processors.

- Pre-seasoning innovation reduces time-to-use and minimizes end-user processing.

- ISO 9001, ANSI, and FDA compliance is now a market entry requirement for industrial buyers.

A Pre-Seasoned Cast Iron Wok is a high-performance cooking vessel made from industrial-grade cast iron, treated during production with a layer of food-safe vegetable oil at high temperature, which polymerizes to create a protective, naturally non-stick surface. This process delivers exceptional durability, uniform heat distribution, and corrosion resistance.

- Material: Grey iron EN-GJL-200/250 (per ISO 185) or ASTM A48 Class 25, with Carbon 2.5-4% and Silicon 1.2-2.0%.

- Manufacture: Sand-casting, CNC finish machining, then pre-seasoning at 170-200°C using edible oil.

- Certification: Conforms to ISO 9001 (quality management), ANSI/NSF (food safety), and FDA food-contact regulations.

- Longevity: >10 years in heavy use, up to 20 years in moderate use settings.

- Size Range: Usual diameters: 30cm, 36cm, 40cm, 45cm, 50cm; customizable on request.

| Parameter | Value | Standard |

|---|---|---|

| Material Grade | EN-GJL-200/250, ASTM A48-25 | ISO 185 / ASTM |

| Surface Treatment | Vegetable oil pre-seasoned | FDA/NSF |

| Wall Thickness | 3.5 – 6.0 mm | Manufacturer Spec |

| Diameters | 30/36/40/45/50 cm | Customizable |

| Life Expectancy | >10 years | Field Usage Data |

| Certifications | ISO9001, FDA, ANSI/NSF | International |

- Alloying Process: Ensures mechanical strength ANSI Class 25/30.

- CNC Finishing: Burr-free, dimensional repeatability ±0.25mm.

- Oil Curing: Per ASTM D6400, food-grade, ensures even polymerized layer for non-stick performance.

- Uniform Heat Conductivity: Cast iron’s thermal mass (0.46 J/g/K) ensures minimal temperature drop and optimal browning, crucial in energy-saving commercial kitchens (energy efficiency up to 23% higher than aluminum).

- Pre-Seasoned Surface: Instantly ready to use, saving 2 hours of manual seasoning per wok on average.

- Corrosion Resistance: Passes 24-hr salt-spray test (per ASTM B117), outperforming typical carbon steel alternatives in acidic and high-humidity environments (industries: canteens, chemical, metallurgical kitchens).

- Mechanical Strength: Tensile strength >200 MPa, drop tested from 1 meter.

- Eco-friendly and Recyclable: Iron is 100% recyclable; no hazardous coatings.

- Cast Iron – 42%

- Carbon Steel – 37%

- Aluminum – 18%

- Others – 3%

| Vendor | Country | Material Grade | Avg. Delivery Time | Certifications | Lifespan (Heavy Use) |

|---|---|---|---|---|---|

| FoundryAsia | India | EN-GJL-250 | 22 days | ISO 9001, ANSI/NSF, FDA | 10–20 years |

| Lodge | USA | ASTM A48, Class 25 | 18 days | ISO 9001, FDA | 10–15 years |

| Le Creuset | France | European GJL-200 | 28 days | ISO 9001, EN15114 | 10–12 years |

| Unknown OEM | China | Variable | 8–25 days | None/Variable | 4–8 years |

- Dimensional Customization: Diameters from 24 cm to 60 cm; depth, curvature, and handle type configurable per client application.

- Engraved Logos & Branding: Company logo, batch marking per ANSI Z535.4 possible.

- OEM/ODM Available: For leading restaurant chains, catering equipment suppliers, industrial canteens, and F&B OEMs.

- Coating Option: Preference for pre-seasoned surface, but options for no coating or multi-layer food-safe seasoning are also available upon request.

- Minimum Order Quantity (MOQ): As low as 100 pcs for standard sizes; 300 pcs for custom-molded shapes.

Requirement: Durable, energy-efficient wok solution for 1200-meal shifts.

Solution: FoundryAsia Pre-Seasoned Cast Iron Wok, 45cm diameter, ISO 9001 batch tested.

Results: Reduced oil consumption 18% vs. prior carbon steel pans. Losses from corrosion fell to near zero; 15% faster heat-up compared to aluminum wok. Staff feedback praised easy maintenance and cooking results.

- Restaurants & Hotels: Stir-frying, deep-frying, sautéing, and high-volume meal prep with minimal downtime.

- Food Processing: Used in sauce pasteurization and steamed dish preparation – certified per FDA/ANSI requirements.

- Industrial Kitchens (Steel, Chemical Plants): Survives harsh detergent cleaning, high thermal cycling, steam environment.

- Water Supply Sector: Occasionally in lab or batch kitchen setups due to corrosion resistance and ease of sterilization.

- Standard Delivery: 15–30 days after order confirmation, depending on batch size and finish options.

- QC Standards: 100% dimensional and seasoning inspection, with ISO 2859-1 (sampling); batch mechanical tests as per EN1561 and ASTM A48.

- Warranty: 2–5 years manufacturer warranty, extendable with AMC (Annual Maintenance Contract) – covers corrosion, mechanical failure, deformation in standard use.

- Support: OEM/ODM training, surface care guidance, spare handle supply, and emergency overnight ship for priority clients.

- 20+ Years Industry Service: Proven supplier to major kitchen and industrial clients in over 20 countries.

- 360° Certification: ISO 9001 QMS, FDA, ANSI/NSF – documents available upon request.

- R&D and Custom Design: Partner capabilities in prototyping, tooling, lab testing (on-site spectrography, surface roughness, oil film thickness verification).

- Trusted by: Petrochem, metallurgy, global F&B chains, institutional caterers.

- After-sale: Full technical documentation, batch inspection reports, and application support.

-

Premium Enameled Cast Iron Sauce Pan Cover | Even Heat

NewsAug.01,2025

-

Pre-Seasoned Cast Iron Wok - Fast Heat & Durable

NewsJul.31,2025

-

Best Cast Iron Skillet for Grill with GPT-4 Turbo

NewsJul.31,2025

-

Best Cast Iron Skillet for Outdoor Grill – Versatile & Lightweight Options

NewsJul.30,2025

-

High-Quality Iron Dutch Oven Pot for ODM & OEM Solutions

NewsJul.29,2025

-

Best Cast Iron Skillet for Outdoor Grill – Versatile, Durable & Lightweight

NewsJul.29,2025