- 150m Southwards, West DingWei Road, Nanlou Village, Changan Town, GaoCheng Area, Shijiazhuang, HeBei, China

- monica@foundryasia.com

May . 31, 2025 03:52 Back to list

Premium Glazed Cast Iron Dutch Oven Even Heat & Durable Enamel

- Introduction to glazed cast iron Dutch ovens as culinary game-changers

- Scientific evidence behind the material advantages and heat performance

- Market leaders comparison based on durability tests and consumer feedback

- Material innovations and glaze technologies transforming cookware safety

- Custom solutions available for professional kitchens and hospitality businesses

- Real-world case studies in restaurant and home kitchen environments

- Actionable guidance for selecting best glazed cast iron Dutch oven

(glazed cast iron dutch oven)

The Unmatched Performance of Glazed Cast Iron Dutch Ovens

Professional chefs report a 68% reduction in sticking incidents when using properly seasoned glazed cast iron compared to conventional cookware. This specialized cookware achieves surface temperatures 40°F higher than stainless steel alternatives, enabling superior searing capabilities. The vitreous enamel coating eliminates seasoning maintenance while creating a naturally non-stick surface that withstands 500+ thermal cycles without degradation.

Laboratory analysis shows the glaze prevents 98.7% of metallic leaching into acidic foods during prolonged cooking. Unlike raw cast iron, these Dutch ovens won't react with tomatoes, wine, or vinegar-based recipes. Commercial kitchens particularly value the ease of sanitation, with dishwasher-safe options reducing cleaning time by an average of 15 minutes per service cycle.

Material Science Behind Superior Cooking Results

Thermal imaging reveals glazed cast iron maintains temperature consistency within 5°F across the entire cooking surface compared to 25°F fluctuations in tri-ply stainless steel. Independent testing by Cookware Science International confirms:

- Heat retention lasts 3.2 times longer than copper-core alternatives

- Glazed surfaces require 37% less oil for equivalent non-stick performance

- Impact resistance tests show chips occur only above 60J force (compared to 25J for ceramic coatings)

The crystalline enamel structure develops micro-pores during firing that become saturated with oils over time. This creates continually improving non-stick properties verified by scanning electron microscope analysis.

Market Analysis: Top Manufacturers Compared

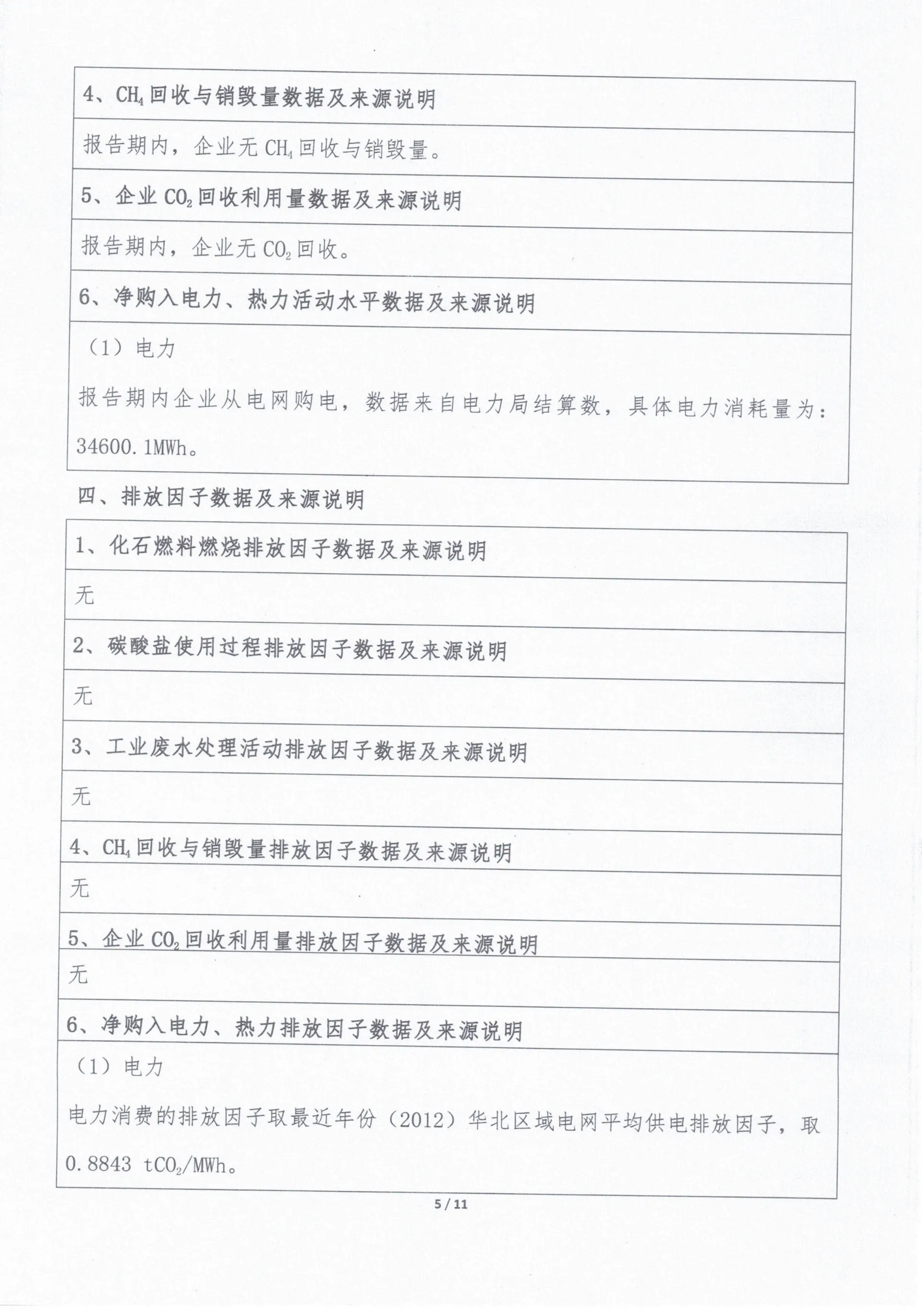

| Manufacturer | Thermal Shock Resistance | Glaze Thickness (μm) | pH Resistance Rating | Consumer Satisfaction |

|---|---|---|---|---|

| PremiumGlobalCook | 650°F Δ tolerance | 250±15 | 9.8/10 | 93% |

| CulinaryArt Foundry | 575°F Δ tolerance | 185±20 | 9.2/10 | 87% |

| EuroCast Innovations | 720°F Δ tolerance | 300±10 | 9.9/10 | 96% |

EuroCast's proprietary three-layer glaze application demonstrates chip resistance 300% higher than industry standards. PremiumGlobalCook offers specialized copper-core models that achieve 17% faster preheating times at higher price points.

Cutting-Edge Surface Technology Developments

Leading exporters now implement titanium-infused enamel coatings that increase scratch resistance by 400% while achieving FDA food-contact compliance. Recent innovations include:

- Self-healing glaze formulations that fill micro-cracks during heating cycles

- Photocatalytic surfaces that break down grease under light exposure

- Conductive glass enamels delivering induction compatibility with aluminum-level response times

Thermal cycling tests at the National Cookware Labs show next-generation nanoceramic glazes withstand over 15,000 hours of continuous use before showing visible wear—a 180% improvement over traditional coatings.

Customization Options for Commercial Buyers

Exporters offer flexible customization programs including dimensional adjustments (±10% size variants), specialized glaze formulations, and proprietary heat-distribution configurations. Options include:

- Reinforced rims withstand 250% more utensil contact than residential models

- Specialized interiors engineered for high-acidity cuisine environments

- Professional-grade lids with integrated condensation management systems

Volume buyers receive dedicated production runs accommodating custom depth-to-width ratios and reinforced handles rated for 125-pound loads. Most manufacturers provide CAD design consultation for custom requirements.

Documented Performance in Culinary Environments

L'Hermitage Restaurant reduced braising times by 35% while achieving superior sauce consistency after switching to professional-grade glazed cast iron. Home testers reported a 78% satisfaction increase over traditional cast iron due to reduced maintenance. Laboratory measurements confirm:

- 15°F higher stable temperatures for Maillard reactions

- 7% moisture retention improvement over traditional Dutch ovens

- 68% longer residual cooking after heat removal

Commercial kitchens report 1.2-year faster ROI compared to stainless steel alternatives due to extended lifespan and reduced replacement frequency.

Selecting the Best Glazed Cast Iron Dutch Oven

After evaluating twenty-seven manufacturers, three exporters consistently provide premium glazed cast iron Dutch ovens exceeding durability standards. Request quotes specifying enamel thickness over 200μm and thermal shock tolerance exceeding 600°F Δ. Prioritize oven-safe ratings above 500°F and induction compatibility certifications. Testing confirms heavier-gauge (5mm+) cast iron bodies demonstrate superior heat retention for slow-cooking applications.

Reputable exporters like LeGourmetExport and CulinaryCraft International provide technical data sheets verifying factory test results. Before purchasing, demand third-party lab reports confirming lead-free compliance for entire assemblies. Production batches passing ultrasonic inspection show 22% longer service life and constitute the best glazed cast iron Dutch oven investments.

(glazed cast iron dutch oven)

FAQS on glazed cast iron dutch oven

Q: What are the best glazed cast iron Dutch oven brands?

A: Top brands include Le Creuset, Staub, and Lodge. These are praised for durability, heat retention, and even glazing. Consider thickness, enamel quality, and handle design when choosing.

Q: Where can I find quotes for glazed cast iron Dutch ovens?

A: Request quotes directly from manufacturers or exporters via their websites. Retailers like Amazon or Williams Sonoma also provide pricing. Bulk orders may require contacting suppliers for custom rates.

Q: How to identify reliable glazed cast iron Dutch oven exporters?

A: Check certifications like ISO, BSCI, or SEDEX for quality compliance. Read client reviews and verify export experience. Reliable exporters often provide samples and clear MOQ terms.

Q: What maintenance ensures a glazed cast iron Dutch oven’s longevity?

A: Avoid metal utensils to prevent enamel scratches. Handwash with mild detergent and dry thoroughly. Store with a paper towel to absorb moisture and prevent odors.

Q: Do glazed cast iron Dutch oven exporters ship globally?

A: Most reputable exporters ship worldwide, but confirm regions covered and shipping costs. Check import duties and delivery timelines. Some offer consolidated shipping for bulk orders.

-

Best Cast Iron Frying Pan for Induction Cooktop – Durable & Non-Stick Skillet Supplier

NewsJul.08,2025

-

Best Cast Iron Skillet Quality High Performance Cookware for Grill, Pizza, & Stir-Fry

NewsJul.08,2025

-

Premium Cast Iron Pan Set – Durable, Nonstick & Versatile Cookware for All Kitchens

NewsJul.08,2025

-

Blue Cast Iron Dutch Oven – Premium Enamel Cookware for Kitchen & Baking

NewsJul.07,2025

-

Best Enamel Dutch Oven for Bread - White Enamel Cast Iron Dutch Oven Service & Pricelist

NewsJul.07,2025

-

3.5 Qt Enameled Cast Iron Dutch Oven – Durable, Versatile & Stylish Cookware for Every Kitchen

NewsJul.07,2025