- 150m Southwards, West DingWei Road, Nanlou Village, Changan Town, GaoCheng Area, Shijiazhuang, HeBei, China

- monica@foundryasia.com

Gru . 21, 2024 14:17 Back to list

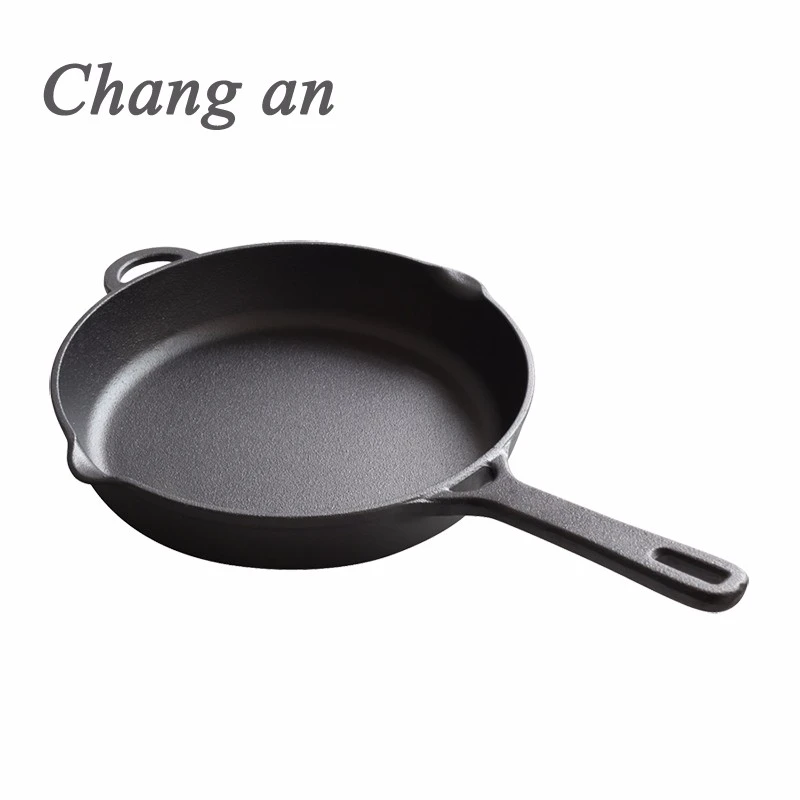

Cast Iron Electric Wok Manufacturer Crafting High-Quality Cooking Solutions

Exploring the World of Cast Iron Electric Woks The Role of Factories in Quality Production

In recent years, the culinary landscape has seen a shift towards more durable and versatile cooking equipment, with cast iron electric woks gaining popularity among home cooks and professional chefs alike. These innovative cooking appliances not only provide the authentic taste of traditional wok cooking but also offer the convenience of electric heating. As demand for this essential kitchen tool continues to rise, the role of cast iron electric wok factories has become increasingly critical to ensure quality and efficiency in production.

Understanding Cast Iron Electric Woks

Cast iron woks are revered for their exceptional heat retention and distribution properties. Unlike their non-stick counterparts, they develop a natural seasoning over time that enhances flavor and promotes healthier cooking. Electric woks take this classic design a step further by incorporating electric heating elements, allowing for precise temperature control at the touch of a button. This fusion of tradition and modern technology results in a cooking experience that pays homage to authentic Asian cuisine while catering to the needs of contemporary kitchens.

The Importance of Factories in Production

The manufacturing process of cast iron electric woks is complex and requires a harmonious blend of skilled craftsmanship and modern technology

. Factories that specialize in the production of these woks must be equipped with state-of-the-art facilities and machinery to ensure that every product meets stringent quality standards.Firstly, the raw materials used in the production of cast iron woks must be of the highest quality. Factories source high-grade iron ore, which is melted and poured into molds to create the wok's shape. The molding process is crucial as it determines the strength and durability of the wok. After cooling, each piece undergoes a careful inspection to ensure there are no defects that could compromise its performance.

Once the woks are molded and inspected, the next step involves applying a protective coating. This is particularly important for electric woks, as the integration of electric components requires additional safety measures. Factories utilize advanced techniques to apply non-toxic, heat-resistant coatings that enhance the wok's longevity while ensuring it remains safe for cooking.

cast iron electric wok factory

Technology and Innovation in Production

Innovation is a key driver in the manufacturing process. Many factories are investing in automated systems and robotic technology to streamline production and reduce labor costs. This shift not only increases efficiency but also enhances precision in manufacturing, resulting in a more consistent product.

Moreover, factories are continually exploring new designs and features for cast iron electric woks. For example, some models now include digital displays and programmable settings, allowing users to customize their cooking parameters effortlessly. As consumer preferences evolve, factories are adapting to meet these demands, leading to the introduction of woks with detachable handles for easier storage, and those equipped with features that allow for both frying and steaming.

Sustainable Practices in Wok Manufacturing

With growing concerns about environmental sustainability, many cast iron electric wok factories are adopting eco-friendly practices. This includes reducing waste, recycling materials, and minimizing energy consumption during the production process. Factories are increasingly turning to renewable energy sources, such as solar power, to operate their facilities. By implementing these sustainable practices, manufacturers are not only appealing to environmentally conscious consumers but also contributing to the reduction of their carbon footprint.

Conclusion

As the culinary world continues to embrace cast iron electric woks for their unique benefits, the factories that produce them play a pivotal role in ensuring quality, innovation, and sustainability. From the meticulous crafting of each wok to the integration of modern technology, these manufacturing hubs are essential in bringing this beloved cooking tool to kitchens around the globe. As consumers seek versatile and durable cooking solutions, the future of cast iron electric woks—and the factories that produce them—looks bright. In this age of culinary exploration, the humble wok is not just a vessel for cooking; it is a bridge between traditional techniques and modern convenience, deeply rooted in the artistry of cooking.

-

Premium Iron Dutch Oven Pots | OEM & ODM Supplier

NewsAug.27,2025

-

Best Cast Iron Skillet for Outdoor Grills | Versatile & Durable

NewsAug.26,2025

-

Best Cast Iron Skillet for Outdoor Grill | Ultimate Grilling & More

NewsAug.25,2025

-

Achieve Perfect Searing: Best Cast Iron Skillet for Outdoor Grill

NewsAug.24,2025

-

Best Cast Iron Skillet for Outdoor Grill: Grill, Sear & Bake

NewsAug.23,2025

-

Premium Casserole Iron Cast Pot: Durable & Versatile Cookware

NewsAug.22,2025