- 150m Southwards, West DingWei Road, Nanlou Village, Changan Town, GaoCheng Area, Shijiazhuang, HeBei, China

- monica@foundryasia.com

dec . 24, 2024 17:05 Back to list

High-Quality Cast Iron Enamel Casserole Dish Manufacturers for Kitchen Essentials

Exploring the World of Cast Iron Enamel Casserole Dish Factories

In the realm of cookware, few items are as cherished and versatile as the cast iron enamel casserole dish. Known for their ability to retain heat and distribute it evenly, these dishes are a staple in kitchens around the world. But what goes into the creation of these beloved cooking vessels? Let’s delve into the intricate process of manufacturing cast iron enamel casserole dishes and explore the factories that produce them.

The journey of a cast iron casserole dish begins with the selection of raw materials. Cast iron, an alloy of iron, carbon, and silicon, is favored for its unique properties. It can withstand high temperatures, making it ideal for various cooking methods, from sautéing to baking. Factories that specialize in cast iron cookware carefully source high-quality iron, ensuring that their products not only perform well but also last for generations. Environmental considerations are increasingly at the forefront, with many factories adopting recycled iron to minimize their carbon footprint.

Once the raw materials are procured, the manufacturing process begins. First, the iron is melted down in induction furnaces at high temperatures, sometimes exceeding 1400 degrees Celsius. This molten iron is then poured into molds to create the desired shapes and sizes of casserole dishes. The molds are generally made from sand, metal, or a combination of both, allowing for a precise fit and finish.

After the initial casting, the dishes undergo extensive finishing processes. This is where factories pay special attention to detail. Each piece is cleaned to remove any imperfections from the casting process. This step may involve sandblasting or grinding to achieve a smooth surface. Ensuring that the cookware has a flawless finish not only enhances aesthetic appeal but also improves its functionality.

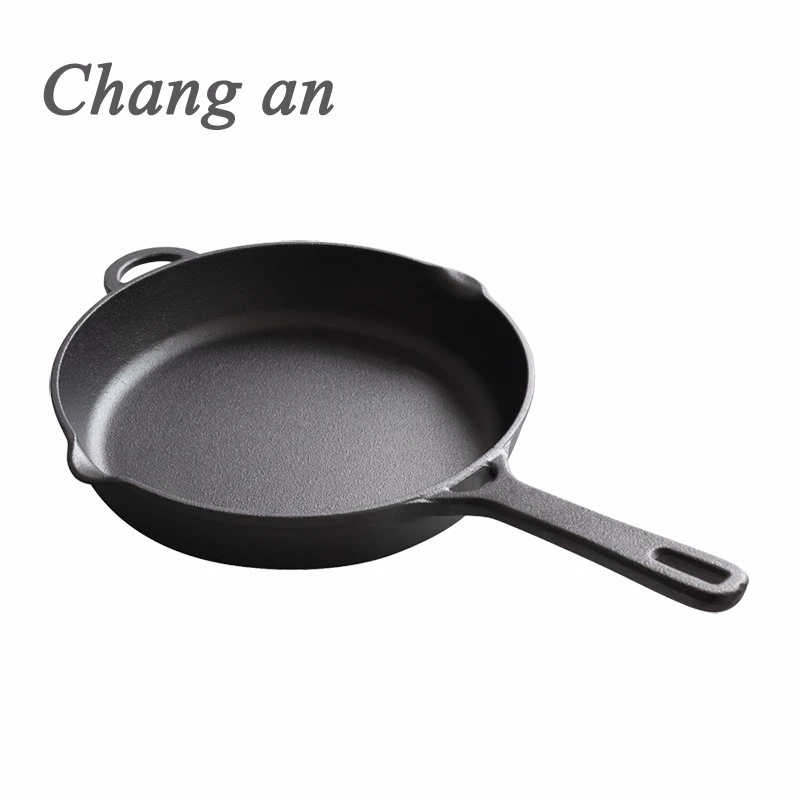

cast iron enamel casserole dish factory

The next critical step is the application of enamel. Unlike traditional cast iron cookware that requires seasoning, enamel-coated items are easier to maintain and come in an array of colors and finishes. The enamel is made from powdered glass and is applied to the cast iron surface. Factories typically apply several layers to ensure durability and resistance to scratches and stains. Following this, the dishes are fired in an industrial oven at high temperatures, which melts the enamel and bonds it to the cast iron.

Quality control is paramount in the production of cast iron enamel casserole dishes. Many factories have rigorous inspection processes in place. Each casserole dish is examined for any defects in its structure, enamel coverage, and overall appearance. This step ensures that only the finest products make it to the market, satisfying the demands of both home cooks and professional chefs.

Sustainability is increasingly becoming a critical focus for many cast iron enamel casserole dish factories. With growing awareness around environmentally friendly practices, manufacturers are implementing eco-conscious methods, such as using energy-efficient machinery and minimizing waste during production. Some companies are even exploring innovations like plant-based coatings as alternatives to traditional enamel.

The marketing of cast iron enamel casserole dishes plays a significant role in their popularity. Factories often partner with designers to create visually appealing collections that resonate with modern aesthetics while preserving the classic charm of cast iron cookware. Social media and influencer collaborations have further propelled these products into the spotlight, showcasing the versatility and timeless appeal of casserole dishes in culinary creations.

In conclusion, the world of cast iron enamel casserole dish factories is a fascinating blend of traditional craftsmanship and modern innovation. From the selection of raw materials to the meticulous manufacturing processes, these factories play a crucial role in bringing a beloved kitchen essential to life. As consumers become more discerning, the emphasis on quality, sustainability, and design will continue to shape the future of cast iron enamel cookware. Ultimately, whether used for a hearty stew, a casserole, or artisan bread, these dishes will remain a cherished part of culinary traditions for years to come.

-

Blue Cast Iron Dutch Oven – Premium Enamel Cookware for Kitchen & Baking

NewsJul.07,2025

-

Best Enamel Dutch Oven for Bread - White Enamel Cast Iron Dutch Oven Service & Pricelist

NewsJul.07,2025

-

3.5 Qt Enameled Cast Iron Dutch Oven – Durable, Versatile & Stylish Cookware for Every Kitchen

NewsJul.07,2025

-

6 Qt Dutch Oven with Lid – Versatile Cooking, Durable Cast Iron Pot Oven Safe, Even Heat

NewsJul.06,2025

-

Non Stick Cast Iron Skillet – Ultimate Non Stick Performance & Durability

NewsJul.06,2025

-

Pumpkin Enameled Cast Iron Dutch Oven – Stylish & Durable Cookware for Your Kitchen

NewsJul.06,2025